Aaron: +86-18129983931

Max: +86-18922922459

Micro Screws

Micro Screws

Big Head Screws

Big Head Screws

Construction Screws

Construction Screws

CNC Lathe Machining Parts

CNC Lathe Machining Parts

Cold Forged and Undergo Secondary Processing Products

Cold Forged and Undergo Secondary Processing Products

Multi Station Cold Heading Screws

Multi Station Cold Heading Screws

Step Screw

Step Screw

Automatic Lathe Machining Parts

Automatic Lathe Machining Parts

High Difficulty Challenge Cold Heading Fasteners

High Difficulty Challenge Cold Heading Fasteners

New Tech Fasteners

New Tech Fasteners

Machine Screws

Machine Screws

Socket Cap Screws

Socket Cap Screws

Hexagon Socket Set Screws

Hexagon Socket Set Screws

Pull Out Rivet

Pull Out Rivet

Self Tapping Screws

Self Tapping Screws

Hex Bolts

Hex Bolts

Self Drilling Screws

Self Drilling Screws

Eye Bolts

Eye Bolts

U-bolts

U-bolts

Threaded Sheath

Threaded Sheath

Hex Nut

Hex Nut

Hex Long Nut

Hex Long Nut

Pull Rivet Nut

Pull Rivet Nut

Square Nuts

Square Nuts

Combination Screws

Combination Screws

Pin

Pin

Nylon Locking Nuts

Nylon Locking Nuts

Pressure Rivet Nuts

Pressure Rivet Nuts

Cage Nut

Cage Nut

Welding Screws

Welding Screws

Butterfly Screw

Butterfly Screw

American Standard Butterfly Nut

American Standard Butterfly Nut

Expansion Screw

Expansion Screw

Plug Screw

Plug Screw

Stainless Steel Washer

Stainless Steel Washer

Double Overlap Anti-Loosening Washers

Double Overlap Anti-Loosening Washers

Waterproof and Anti-Drop Screws

Waterproof and Anti-Drop Screws

Super Corrosion-Resistant Screws

Super Corrosion-Resistant Screws

New Type Switchgear

New Type Switchgear

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Furniture Simple Assembly and Disassembly Connector

Furniture Simple Assembly and Disassembly Connector

Micro Vibration Absorber

Micro Vibration Absorber

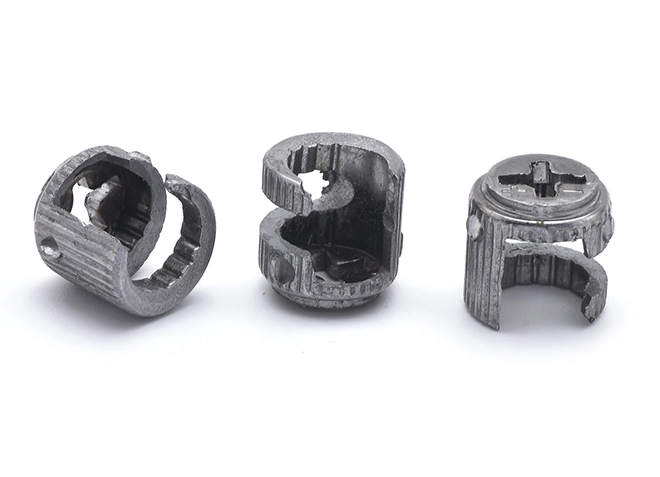

65Mn Material Furniture Connector

65Mn Material Furniture Connector

Counter Table Base

Counter Table Base

Furniture Connector Nut with Plastic Sleeve

Furniture Connector Nut with Plastic Sleeve

Furniture Horizontal Hole Nut

Furniture Horizontal Hole Nut

Furniture Connecting Screw

Furniture Connecting Screw

Furniture Connecting Nut Seat

Furniture Connecting Nut Seat

Double Stack Wheels Used On Furniture

Double Stack Wheels Used On Furniture

Components Used On Furniture

Components Used On Furniture

Connection Buckle

Connection Buckle

Internal Hexagonal Spiral Screw

Internal Hexagonal Spiral Screw

Iron Colored Carbon Steel Four Claw Nut

Iron Colored Carbon Steel Four Claw Nut

Iron Furniture Three Combination Nut Seat

Iron Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

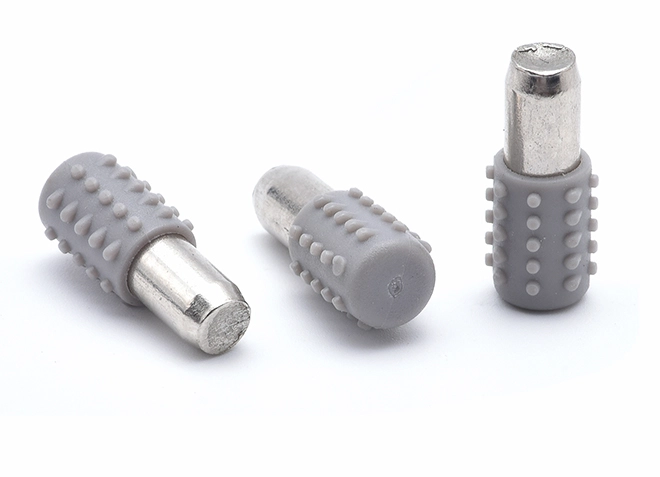

Dowel Pin+ Gray Elephant Rubber Sleeve

Dowel Pin+ Gray Elephant Rubber Sleeve

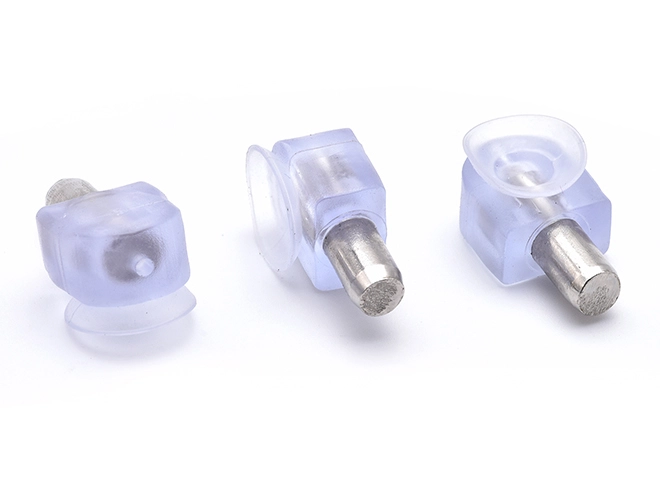

Dowel Pin+ Transparent Elephant Rubber Sleeve

Dowel Pin+ Transparent Elephant Rubber Sleeve

Injection Molded Furniture Foot Pad Screw

Injection Molded Furniture Foot Pad Screw

A 304 American Standard Butterfly Nut, also known as a wing nut, is crafted from 304-grade stainless steel, known for its excellent resistance to corrosion and oxidation. This type of nut is distinguished by its two large, wing-like projections that allow it to be tightened and loosened by hand without the need for tools. This feature makes butterfly nuts particularly useful in applications where fast, frequent adjustments or disassembly is required.

Material Strength

304 Stainless Steel: Known for its good mechanical properties and corrosion resistance, 304 stainless steel has a tensile strength of approximately 70,000 psi (480 MPa). This makes it suitable for various applications where moderate strength and resistance to environmental factors are required.

Design and Dimensions

Dimensions: The load capacity of a butterfly nut is directly related to its size and thread dimensions. For American Standard threads, common sizes include 1/4"-20, 5/16"-18, and 3/8"-16, among others. Larger dimensions generally provide higher load capacities.

Design Features: The design of a butterfly nut, which includes wings for manual tightening, impacts its ability to handle loads. The load capacity is also affected by the thickness and overall design of the nut.

Load Capacity

General Capacity: While exact load capacities can vary based on specific dimensions and design, a general rule of thumb for standard 304 stainless steel nuts (not specifically butterfly nuts) is that they can handle a load proportional to their size and thread type. For instance, a 1/4"-20 304 stainless steel nut might handle around 500 to 800 pounds of axial load, but this can vary.

Butterfly Nut Specifics: Butterfly nuts are generally used for applications requiring frequent adjustments or where manual tightening is needed. They are not typically designed for heavy-load applications compared to other types of nuts and fasteners.

Factors Affecting Strength

Installation Conditions: Proper installation and torque application are crucial. Over-tightening can lead to damage, while under-tightening may result in a loose connection.

Environmental Conditions: Although 304 stainless steel is corrosion-resistant, extreme environments or conditions could affect its performance. For critical applications, consider using nuts specifically designed for high-strength or high-corrosion environments.

For precise load capacity and strength values, consulting manufacturer specifications or engineering guidelines specific to the butterfly nut's size and design is essential.

Thread specification (d) | |

| P | Coarse pitch |

| dk | Maximum value |

| Minimum value | |

| ds | Maximum value |

| Minimum value | |

| L | Maximum value |

| Minimum value | |

| y | Maximum value |

| Minimum value | |

| y1 | Maximum value |

| Minimum value | |

| k | Maximum value |

| Minimum value | |

| m | Maximum value |

| Minimum value | |

| r | ≈ |

| R | ≈ |

①, Material: a) Forgeable cast iron GT: GTS or GTW is determined by the manufacturer; b) Steel St: Forging or cold working is determined by the manufacturer; c) Copper-zinc alloy CuZn: Forgeable alloy or cast alloy is determined by the manufacturer; d) Austenitic stainless steel A: Grade is determined by the manufacturer | |

| M4 | M5 | M6 | M8 | M10 | M12 | M16 | M20 | M24 |

| 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.5 | 3 |

| 8 | 11 | 13 | 16 | 20 | 23 | 29 | 35 | 44 |

| 6 | 8 | 10 | 13 | 17 | 20 | 26 | 32 | 41 |

| 7 | 9 | 11 | 12.5 | 16.5 | 19.5 | 23 | 29 | 37.5 |

| 5.5 | 7.5 | 9 | 10.5 | 14.5 | 17.5 | 21 | 27 | 35 |

| 20 | 26 | 33 | 39 | 51 | 65 | 73 | 90 | 110 |

| 18 | 24 | 30 | 36 | 48 | 62 | 70 | 86 | 106 |

| 1.9 | 2.3 | 2.3 | 2.8 | 4.4 | 4.9 | 6.4 | 6.9 | 9.4 |

| 1.1 | 1.5 | 1.5 | 2 | 3.6 | 4.1 | 5.6 | 6.1 | 8.6 |

| 2.3 | 2.8 | 3.3 | 4.4 | 5.4 | 6.4 | 7.5 | 8 | 10.5 |

| 1.7 | 2.3 | 2.7 | 3.6 | 4.6 | 5.6 | 6.5 | 7 | 9.5 |

| 10.5 | 13 | 17 | 20 | 25 | 33.5 | 37.5 | 46.5 | 56.5 |

| 8.5 | 11 | 15 | 18 | 23 | 31 | 35 | 44 | 53.5 |

| 4.6 | 6.5 | 8 | 10 | 12 | 14 | 17 | 21 | 25 |

| 3.2 | 4 | 5 | 6.5 | 8 | 10 | 13 | 16 | 20 |

| 2 | 2.5 | 3 | 3 | 5 | 6 | 7 | 8 | 9 |

| 3 | 4 | 5 | 6 | 8 | 10 | 11 | 14 | 18 |

arron18129983931@gmail.com

arron18129983931@gmail.com

arron18129983931@gmail.com