Aaron: +86-18129983931

Max: +86-18922922459

Micro Screws

Micro Screws

Big Head Screws

Big Head Screws

Construction Screws

Construction Screws

CNC Lathe Machining Parts

CNC Lathe Machining Parts

Cold Forged and Undergo Secondary Processing Products

Cold Forged and Undergo Secondary Processing Products

Multi Station Cold Heading Screws

Multi Station Cold Heading Screws

Step Screw

Step Screw

Automatic Lathe Machining Parts

Automatic Lathe Machining Parts

High Difficulty Challenge Cold Heading Fasteners

High Difficulty Challenge Cold Heading Fasteners

New Tech Fasteners

New Tech Fasteners

Machine Screws

Machine Screws

Socket Cap Screws

Socket Cap Screws

Hexagon Socket Set Screws

Hexagon Socket Set Screws

Pull Out Rivet

Pull Out Rivet

Self Tapping Screws

Self Tapping Screws

Hex Bolts

Hex Bolts

Self Drilling Screws

Self Drilling Screws

Eye Bolts

Eye Bolts

U-bolts

U-bolts

Threaded Sheath

Threaded Sheath

Hex Nut

Hex Nut

Hex Long Nut

Hex Long Nut

Pull Rivet Nut

Pull Rivet Nut

Square Nuts

Square Nuts

Combination Screws

Combination Screws

Pin

Pin

Nylon Locking Nuts

Nylon Locking Nuts

Pressure Rivet Nuts

Pressure Rivet Nuts

Cage Nut

Cage Nut

Welding Screws

Welding Screws

Butterfly Screw

Butterfly Screw

American Standard Butterfly Nut

American Standard Butterfly Nut

Expansion Screw

Expansion Screw

Plug Screw

Plug Screw

Stainless Steel Washer

Stainless Steel Washer

Double Overlap Anti-Loosening Washers

Double Overlap Anti-Loosening Washers

Waterproof and Anti-Drop Screws

Waterproof and Anti-Drop Screws

Super Corrosion-Resistant Screws

Super Corrosion-Resistant Screws

New Type Switchgear

New Type Switchgear

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Furniture Simple Assembly and Disassembly Connector

Furniture Simple Assembly and Disassembly Connector

Micro Vibration Absorber

Micro Vibration Absorber

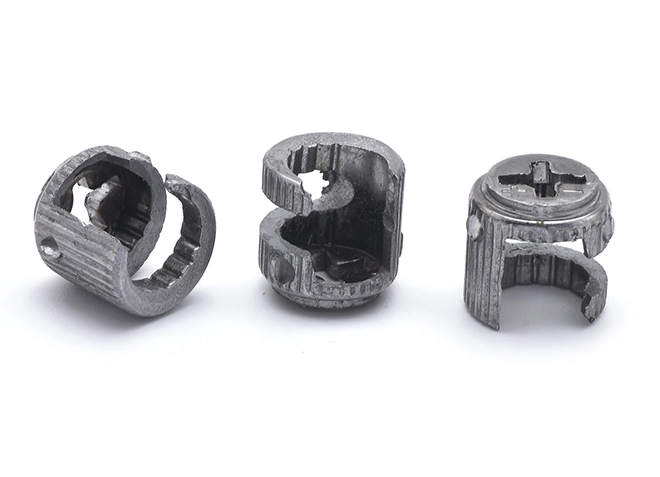

65Mn Material Furniture Connector

65Mn Material Furniture Connector

Counter Table Base

Counter Table Base

Furniture Connector Nut with Plastic Sleeve

Furniture Connector Nut with Plastic Sleeve

Furniture Horizontal Hole Nut

Furniture Horizontal Hole Nut

Furniture Connecting Screw

Furniture Connecting Screw

Furniture Connecting Nut Seat

Furniture Connecting Nut Seat

Double Stack Wheels Used On Furniture

Double Stack Wheels Used On Furniture

Components Used On Furniture

Components Used On Furniture

Connection Buckle

Connection Buckle

Internal Hexagonal Spiral Screw

Internal Hexagonal Spiral Screw

Iron Colored Carbon Steel Four Claw Nut

Iron Colored Carbon Steel Four Claw Nut

Iron Furniture Three Combination Nut Seat

Iron Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

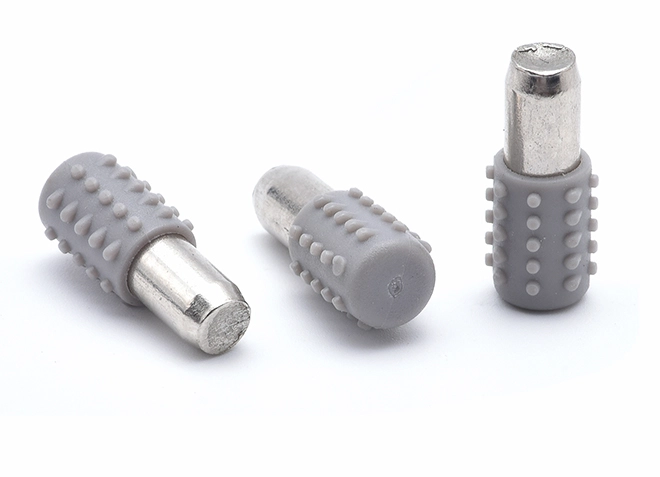

Dowel Pin+ Gray Elephant Rubber Sleeve

Dowel Pin+ Gray Elephant Rubber Sleeve

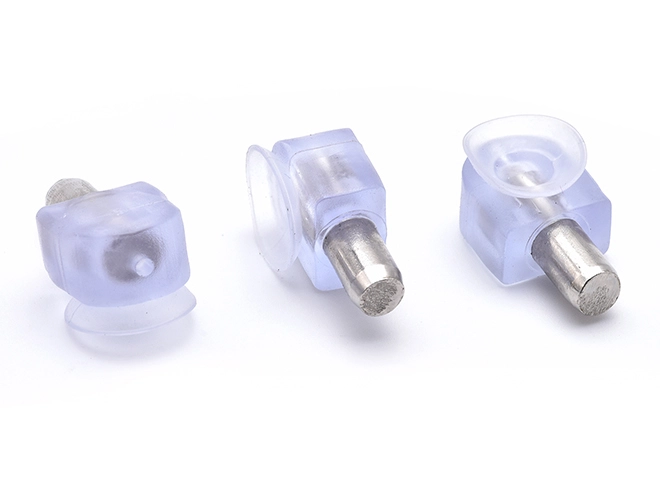

Dowel Pin+ Transparent Elephant Rubber Sleeve

Dowel Pin+ Transparent Elephant Rubber Sleeve

Injection Molded Furniture Foot Pad Screw

Injection Molded Furniture Foot Pad Screw

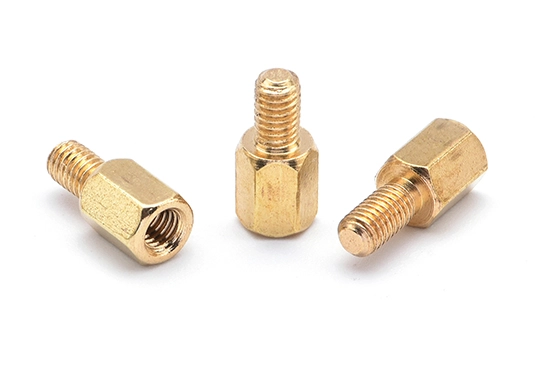

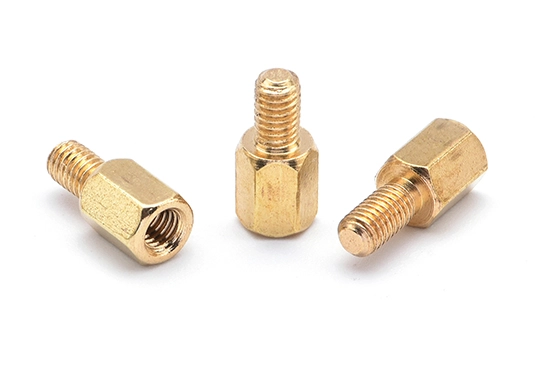

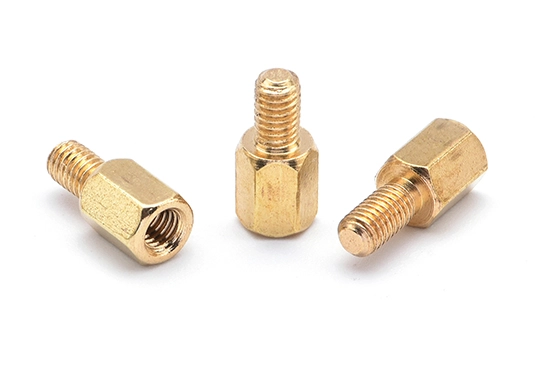

A hexagonal copper isolation column is fabricated by first designing a precise CAD model. High-purity copper is selected for its excellent electrical and thermal conductivity. The hexagonal shape is achieved using precision machining techniques such as CNC milling, ensuring exact dimensions and smooth surfaces. Post-machining, the column undergoes thorough quality inspections to verify dimensional accuracy and surface finish. This ensures the isolation column meets stringent specifications for use in electrical or thermal isolation applications.

Enhanced Structural Integrity: The hexagonal shape provides a robust and stable structure, distributing stress evenly across the column. This geometric configuration helps in maintaining strength and reducing the likelihood of deformation or failure under load.

Improved Load Distribution: The hexagonal design allows for efficient load distribution, which enhances the column's ability to support heavy or distributed loads without significant deflection. This makes them ideal for structural applications requiring stability and durability.

Effective Electrical Isolation: Copper's conductivity is paired with the isolation function, ensuring that the column can effectively separate and isolate electrical components or systems. This isolation prevents unwanted electrical interference and maintains system integrity.

Corrosion Resistance: Copper's natural resistance to corrosion and oxidation contributes to the longevity and durability of the isolation column. This resistance ensures that the column remains effective and structurally sound even in harsh environments.

Aesthetic and Functional Design: The hexagonal shape is not only functional but also aesthetically pleasing. It can be used in architectural and design applications where both performance and appearance are important. The shape can also contribute to more efficient use of space and material.

Ease of Integration: Hexagonal copper isolation columns can be easily integrated into various systems and structures due to their standard shape and dimensions. This versatility facilitates their use in diverse applications, including electrical enclosures, support structures, and mechanical assemblies.

aaron18129983931@gmail.com

aaron18129983931@gmail.com

aaron18129983931@gmail.com