Aaron: +86-18129983931

Max: +86-18922922459

Micro Screws

Micro Screws

Big Head Screws

Big Head Screws

Construction Screws

Construction Screws

CNC Lathe Machining Parts

CNC Lathe Machining Parts

Cold Forged and Undergo Secondary Processing Products

Cold Forged and Undergo Secondary Processing Products

Multi Station Cold Heading Screws

Multi Station Cold Heading Screws

Step Screw

Step Screw

Automatic Lathe Machining Parts

Automatic Lathe Machining Parts

High Difficulty Challenge Cold Heading Fasteners

High Difficulty Challenge Cold Heading Fasteners

New Tech Fasteners

New Tech Fasteners

Machine Screws

Machine Screws

Socket Cap Screws

Socket Cap Screws

Hexagon Socket Set Screws

Hexagon Socket Set Screws

Pull Out Rivet

Pull Out Rivet

Self Tapping Screws

Self Tapping Screws

Hex Bolts

Hex Bolts

Self Drilling Screws

Self Drilling Screws

Eye Bolts

Eye Bolts

U-bolts

U-bolts

Threaded Sheath

Threaded Sheath

Hex Nut

Hex Nut

Hex Long Nut

Hex Long Nut

Pull Rivet Nut

Pull Rivet Nut

Square Nuts

Square Nuts

Combination Screws

Combination Screws

Pin

Pin

Nylon Locking Nuts

Nylon Locking Nuts

Pressure Rivet Nuts

Pressure Rivet Nuts

Cage Nut

Cage Nut

Welding Screws

Welding Screws

Butterfly Screw

Butterfly Screw

American Standard Butterfly Nut

American Standard Butterfly Nut

Expansion Screw

Expansion Screw

Plug Screw

Plug Screw

Stainless Steel Washer

Stainless Steel Washer

Double Overlap Anti-Loosening Washers

Double Overlap Anti-Loosening Washers

Waterproof and Anti-Drop Screws

Waterproof and Anti-Drop Screws

Super Corrosion-Resistant Screws

Super Corrosion-Resistant Screws

New Type Switchgear

New Type Switchgear

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Furniture Simple Assembly and Disassembly Connector

Furniture Simple Assembly and Disassembly Connector

Micro Vibration Absorber

Micro Vibration Absorber

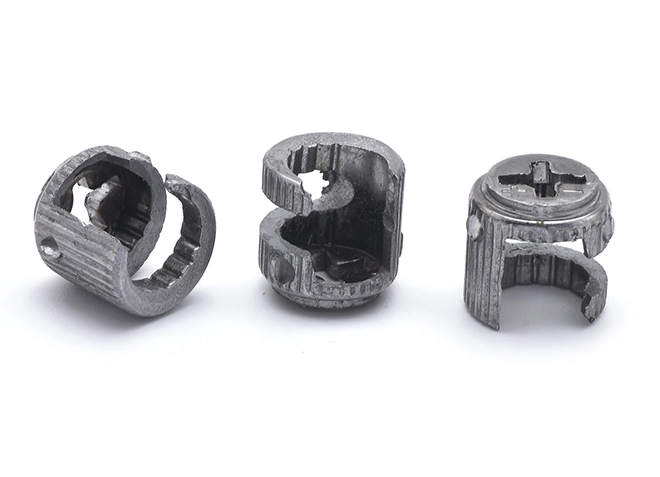

65Mn Material Furniture Connector

65Mn Material Furniture Connector

Counter Table Base

Counter Table Base

Furniture Connector Nut with Plastic Sleeve

Furniture Connector Nut with Plastic Sleeve

Furniture Horizontal Hole Nut

Furniture Horizontal Hole Nut

Furniture Connecting Screw

Furniture Connecting Screw

Furniture Connecting Nut Seat

Furniture Connecting Nut Seat

Double Stack Wheels Used On Furniture

Double Stack Wheels Used On Furniture

Components Used On Furniture

Components Used On Furniture

Connection Buckle

Connection Buckle

Internal Hexagonal Spiral Screw

Internal Hexagonal Spiral Screw

Iron Colored Carbon Steel Four Claw Nut

Iron Colored Carbon Steel Four Claw Nut

Iron Furniture Three Combination Nut Seat

Iron Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

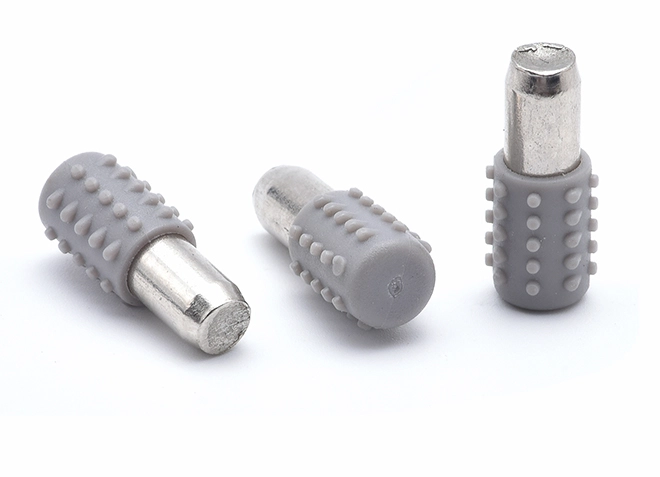

Dowel Pin+ Gray Elephant Rubber Sleeve

Dowel Pin+ Gray Elephant Rubber Sleeve

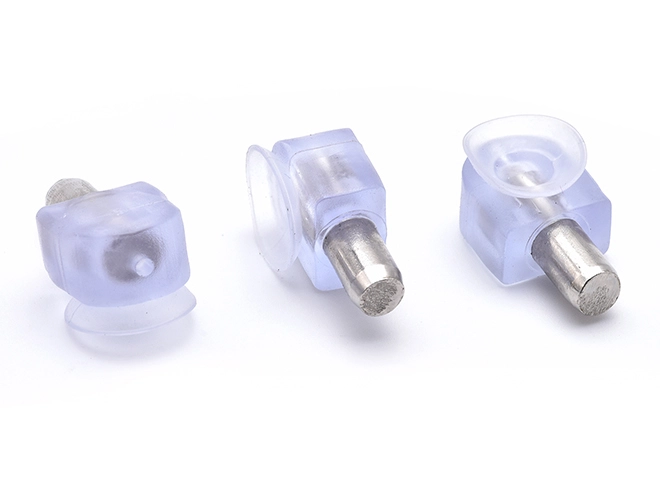

Dowel Pin+ Transparent Elephant Rubber Sleeve

Dowel Pin+ Transparent Elephant Rubber Sleeve

Injection Molded Furniture Foot Pad Screw

Injection Molded Furniture Foot Pad Screw

A Precision Copper Component on a medical device is a meticulously crafted part designed for high accuracy and reliability. Made from high-purity copper, it offers excellent electrical conductivity and biocompatibility. Essential in applications like diagnostic equipment, imaging systems, and patient monitoring devices, this component ensures optimal performance, durability, and safety, meeting stringent medical standards and enhancing overall device functionality.

Electrical Conductivity: Copper's excellent electrical conductivity ensures efficient transmission of electrical signals in medical devices. This is crucial for devices such as pacemakers, diagnostic equipment, and imaging systems, where accurate signal transmission is essential for proper operation.

Heat Dissipation: Precision copper components aid in effective heat management within medical devices. Devices that generate heat, such as those with high-power electronics or laser systems, benefit from copper's high thermal conductivity, which helps in dissipating heat and maintaining optimal operating temperatures.

Mechanical Precision: Copper components are manufactured to tight tolerances, ensuring precise fit and functionality in medical devices. This precision is crucial for components like connectors, pins, and housings, which must align perfectly and function reliably in complex medical assemblies.

Corrosion Resistance: Copper components often undergo treatments or alloying to enhance their corrosion resistance, which is important in medical environments where exposure to bodily fluids or harsh sterilization processes can occur. This ensures longevity and reliable performance of the components.

Biocompatibility: Copper components, when properly processed, can be used in medical devices that require biocompatibility. While not all copper alloys are biocompatible, certain formulations and coatings can make them suitable for use in implants and other devices that come into direct contact with the human body.

Signal Integrity: In diagnostic and monitoring equipment, precision copper components help maintain signal integrity by minimizing electrical noise and interference. This is crucial for accurate readings and data transmission in devices like electrocardiograms (ECGs) and blood glucose monitors.

Durability and Reliability: The mechanical strength and durability of copper components ensure that they can withstand the rigors of medical environments, including repeated use and mechanical stresses. This contributes to the overall reliability and longevity of medical devices.

arron18129983931@gmail.com

arron18129983931@gmail.com

arron18129983931@gmail.com