Aaron: +86-18129983931

Max: +86-18922922459

Micro Screws

Micro Screws

Big Head Screws

Big Head Screws

Construction Screws

Construction Screws

CNC Lathe Machining Parts

CNC Lathe Machining Parts

Cold Forged and Undergo Secondary Processing Products

Cold Forged and Undergo Secondary Processing Products

Multi Station Cold Heading Screws

Multi Station Cold Heading Screws

Step Screw

Step Screw

Automatic Lathe Machining Parts

Automatic Lathe Machining Parts

High Difficulty Challenge Cold Heading Fasteners

High Difficulty Challenge Cold Heading Fasteners

New Tech Fasteners

New Tech Fasteners

Machine Screws

Machine Screws

Socket Cap Screws

Socket Cap Screws

Hexagon Socket Set Screws

Hexagon Socket Set Screws

Pull Out Rivet

Pull Out Rivet

Self Tapping Screws

Self Tapping Screws

Hex Bolts

Hex Bolts

Self Drilling Screws

Self Drilling Screws

Eye Bolts

Eye Bolts

U-bolts

U-bolts

Threaded Sheath

Threaded Sheath

Hex Nut

Hex Nut

Hex Long Nut

Hex Long Nut

Pull Rivet Nut

Pull Rivet Nut

Square Nuts

Square Nuts

Combination Screws

Combination Screws

Pin

Pin

Nylon Locking Nuts

Nylon Locking Nuts

Pressure Rivet Nuts

Pressure Rivet Nuts

Cage Nut

Cage Nut

Welding Screws

Welding Screws

Butterfly Screw

Butterfly Screw

American Standard Butterfly Nut

American Standard Butterfly Nut

Expansion Screw

Expansion Screw

Plug Screw

Plug Screw

Stainless Steel Washer

Stainless Steel Washer

Double Overlap Anti-Loosening Washers

Double Overlap Anti-Loosening Washers

Waterproof and Anti-Drop Screws

Waterproof and Anti-Drop Screws

Super Corrosion-Resistant Screws

Super Corrosion-Resistant Screws

New Type Switchgear

New Type Switchgear

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Furniture Simple Assembly and Disassembly Connector

Furniture Simple Assembly and Disassembly Connector

Micro Vibration Absorber

Micro Vibration Absorber

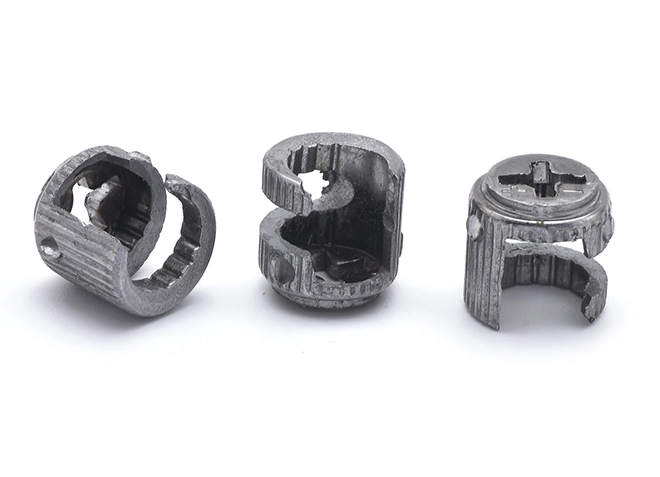

65Mn Material Furniture Connector

65Mn Material Furniture Connector

Counter Table Base

Counter Table Base

Furniture Connector Nut with Plastic Sleeve

Furniture Connector Nut with Plastic Sleeve

Furniture Horizontal Hole Nut

Furniture Horizontal Hole Nut

Furniture Connecting Screw

Furniture Connecting Screw

Furniture Connecting Nut Seat

Furniture Connecting Nut Seat

Double Stack Wheels Used On Furniture

Double Stack Wheels Used On Furniture

Components Used On Furniture

Components Used On Furniture

Connection Buckle

Connection Buckle

Internal Hexagonal Spiral Screw

Internal Hexagonal Spiral Screw

Iron Colored Carbon Steel Four Claw Nut

Iron Colored Carbon Steel Four Claw Nut

Iron Furniture Three Combination Nut Seat

Iron Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

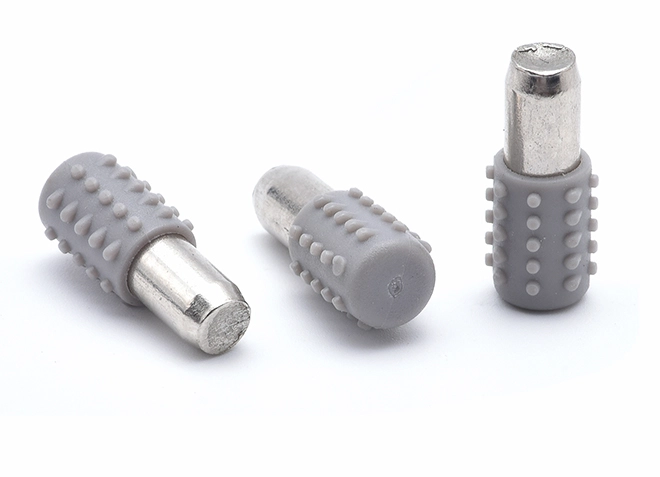

Dowel Pin+ Gray Elephant Rubber Sleeve

Dowel Pin+ Gray Elephant Rubber Sleeve

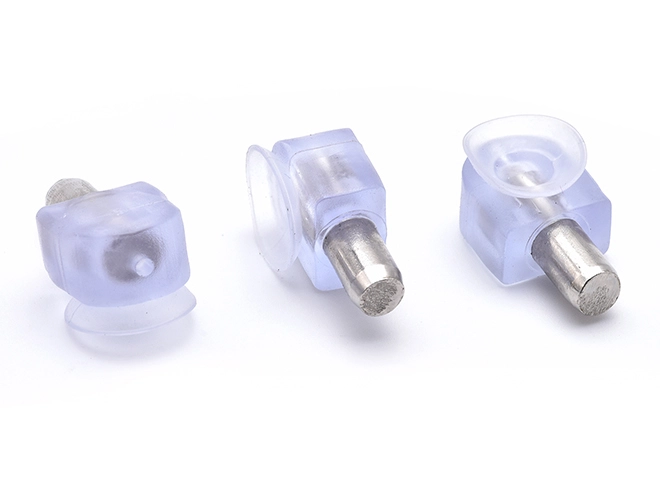

Dowel Pin+ Transparent Elephant Rubber Sleeve

Dowel Pin+ Transparent Elephant Rubber Sleeve

Injection Molded Furniture Foot Pad Screw

Injection Molded Furniture Foot Pad Screw

The through-hole spiral copper component is intricately designed for applications requiring efficient heat dissipation and electrical conductivity. Crafted with meticulous precision using advanced techniques like CNC machining, it features a spiral design with a through-hole at its center. This configuration maximizes surface area for enhanced thermal transfer capabilities while allowing for the passage of fluids or wires through the center. Copper's superior conductivity, corrosion resistance, and durability make it an ideal material choice for industries such as electronics, automotive, and aerospace. These components play crucial roles in optimizing performance and reliability in various systems and equipment.

Complexity in Design and Manufacturing: Achieving the precise spiral pattern and maintaining consistent dimensions requires advanced techniques and complex tooling, making the design and manufacturing process intricate and costly.

Alignment and Assembly Issues: Ensuring proper alignment during assembly is critical; misalignment can affect performance. Integrating these components into existing systems or assemblies requires exact positioning to ensure functionality.

Thermal and Electrical Management: Effective heat dissipation can be difficult due to the spiral design, and maintaining high electrical conductivity throughout the component requires careful design and quality control.

Material Handling and Processing: The varying thicknesses in the spiral design complicate manufacturing and material handling, and processing copper to achieve precise cuts and formations can affect quality and consistency.

Cost Implications: Production costs are higher due to the need for specialized tooling and precision machining. Scaling up production while maintaining quality can be expensive, impacting the overall cost-effectiveness.

Durability and Wear: The spiral design may lead to increased wear and stress concentration, requiring careful material selection and design to ensure durability and longevity.

Compliance and Standards: Meeting industry standards and regulatory requirements for electrical, mechanical, and safety aspects can be challenging, necessitating thorough compliance checks.

arron18129983931@gmail.com

arron18129983931@gmail.com

arron18129983931@gmail.com