Aaron: +86-18129983931

Max: +86-18922922459

Micro Screws

Micro Screws

Big Head Screws

Big Head Screws

Construction Screws

Construction Screws

CNC Lathe Machining Parts

CNC Lathe Machining Parts

Cold Forged and Undergo Secondary Processing Products

Cold Forged and Undergo Secondary Processing Products

Multi Station Cold Heading Screws

Multi Station Cold Heading Screws

Step Screw

Step Screw

Automatic Lathe Machining Parts

Automatic Lathe Machining Parts

High Difficulty Challenge Cold Heading Fasteners

High Difficulty Challenge Cold Heading Fasteners

New Tech Fasteners

New Tech Fasteners

Machine Screws

Machine Screws

Socket Cap Screws

Socket Cap Screws

Hexagon Socket Set Screws

Hexagon Socket Set Screws

Pull Out Rivet

Pull Out Rivet

Self Tapping Screws

Self Tapping Screws

Hex Bolts

Hex Bolts

Self Drilling Screws

Self Drilling Screws

Eye Bolts

Eye Bolts

U-bolts

U-bolts

Threaded Sheath

Threaded Sheath

Hex Nut

Hex Nut

Hex Long Nut

Hex Long Nut

Pull Rivet Nut

Pull Rivet Nut

Square Nuts

Square Nuts

Combination Screws

Combination Screws

Pin

Pin

Nylon Locking Nuts

Nylon Locking Nuts

Pressure Rivet Nuts

Pressure Rivet Nuts

Cage Nut

Cage Nut

Welding Screws

Welding Screws

Butterfly Screw

Butterfly Screw

American Standard Butterfly Nut

American Standard Butterfly Nut

Expansion Screw

Expansion Screw

Plug Screw

Plug Screw

Stainless Steel Washer

Stainless Steel Washer

Double Overlap Anti-Loosening Washers

Double Overlap Anti-Loosening Washers

Waterproof and Anti-Drop Screws

Waterproof and Anti-Drop Screws

Super Corrosion-Resistant Screws

Super Corrosion-Resistant Screws

New Type Switchgear

New Type Switchgear

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Furniture Simple Assembly and Disassembly Connector

Furniture Simple Assembly and Disassembly Connector

Micro Vibration Absorber

Micro Vibration Absorber

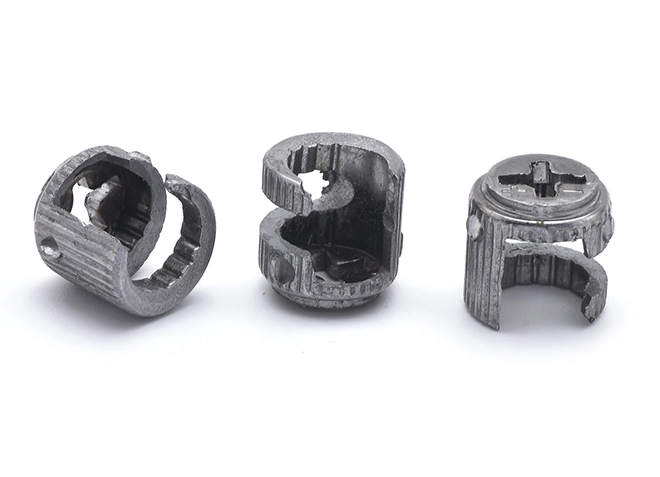

65Mn Material Furniture Connector

65Mn Material Furniture Connector

Counter Table Base

Counter Table Base

Furniture Connector Nut with Plastic Sleeve

Furniture Connector Nut with Plastic Sleeve

Furniture Horizontal Hole Nut

Furniture Horizontal Hole Nut

Furniture Connecting Screw

Furniture Connecting Screw

Furniture Connecting Nut Seat

Furniture Connecting Nut Seat

Double Stack Wheels Used On Furniture

Double Stack Wheels Used On Furniture

Components Used On Furniture

Components Used On Furniture

Connection Buckle

Connection Buckle

Internal Hexagonal Spiral Screw

Internal Hexagonal Spiral Screw

Iron Colored Carbon Steel Four Claw Nut

Iron Colored Carbon Steel Four Claw Nut

Iron Furniture Three Combination Nut Seat

Iron Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

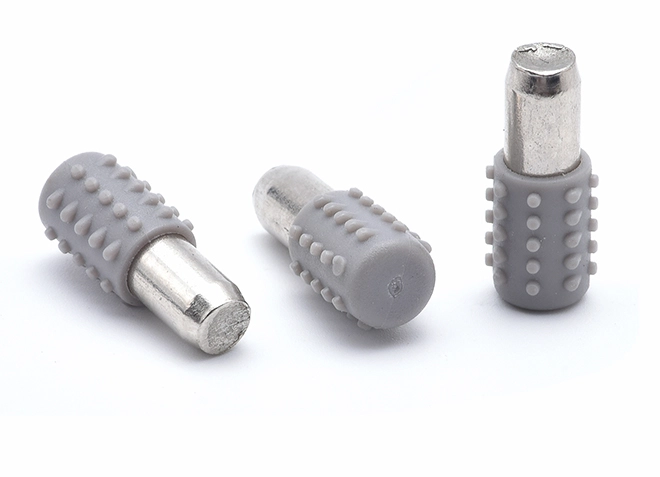

Dowel Pin+ Gray Elephant Rubber Sleeve

Dowel Pin+ Gray Elephant Rubber Sleeve

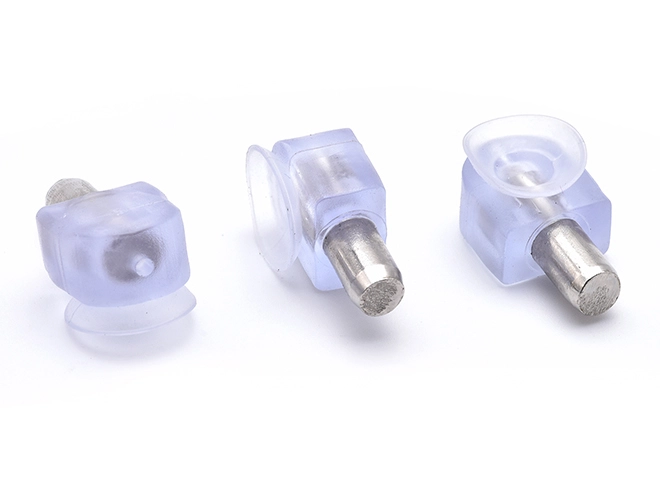

Dowel Pin+ Transparent Elephant Rubber Sleeve

Dowel Pin+ Transparent Elephant Rubber Sleeve

Injection Molded Furniture Foot Pad Screw

Injection Molded Furniture Foot Pad Screw

A non-standard three combination screw is a specialized fastener engineered for unique applications or specific requirements that deviate from standard fastening solutions. Unlike conventional screws, which typically feature a single type of threading, head, and length, the non-standard three combination screw incorporates three distinct elements customized to meet specific needs. These elements may include unconventional thread patterns, specialized heads (such as hexagonal, square, or torx), and unique lengths or diameters tailored to the application.

Assess the Situation: Before removing a non-standard three combination screw, evaluate the condition of the screw and surrounding area. Determine if the screw is damaged or if any special tools are required for removal.

Select the Right Tool: Use the appropriate tool for the screw type, such as a specialized driver or wrench. Ensure the tool fits the screw’s head or drive type to avoid stripping or damaging the screw.

Apply Gentle Pressure: Begin by applying gentle pressure to loosen the screw. Turn the tool counterclockwise to unscrew. If the screw is difficult to remove, apply steady pressure rather than sudden force to avoid damaging the screw or material.

Use Penetrating Oil if Needed: For stubborn screws, apply a penetrating oil or lubricant to help loosen the threads. Allow the oil to sit for a few minutes to penetrate and reduce friction before attempting removal again.

Remove the Screw Carefully: Once the screw is loosened, continue turning it counterclockwise until it is fully removed. Handle the screw carefully to avoid dropping or damaging it.

Inspect the Screw and Hole: After removal, inspect the screw for any damage and the hole or slot for any signs of wear or damage. Ensure that the threads in the hole are not stripped or damaged.

Clean the Area: Clean the area around the screw hole or slot to remove any debris or residual lubricant. This helps in preparing the area for a new screw or for reassembly.

Address Any Issues: If the screw hole or threads are damaged, repair or replace them as needed before installing a new screw. Ensure that the replacement screw fits correctly and that the installation area is in good condition.

arron18129983931@gmail.com

arron18129983931@gmail.com

arron18129983931@gmail.com