Aaron: +86-18129983931

Max: +86-18922922459

Micro Screws

Micro Screws

Big Head Screws

Big Head Screws

Construction Screws

Construction Screws

CNC Lathe Machining Parts

CNC Lathe Machining Parts

Cold Forged and Undergo Secondary Processing Products

Cold Forged and Undergo Secondary Processing Products

Multi Station Cold Heading Screws

Multi Station Cold Heading Screws

Step Screw

Step Screw

Automatic Lathe Machining Parts

Automatic Lathe Machining Parts

High Difficulty Challenge Cold Heading Fasteners

High Difficulty Challenge Cold Heading Fasteners

New Tech Fasteners

New Tech Fasteners

Machine Screws

Machine Screws

Socket Cap Screws

Socket Cap Screws

Hexagon Socket Set Screws

Hexagon Socket Set Screws

Pull Out Rivet

Pull Out Rivet

Self Tapping Screws

Self Tapping Screws

Hex Bolts

Hex Bolts

Self Drilling Screws

Self Drilling Screws

Eye Bolts

Eye Bolts

U-bolts

U-bolts

Threaded Sheath

Threaded Sheath

Hex Nut

Hex Nut

Hex Long Nut

Hex Long Nut

Pull Rivet Nut

Pull Rivet Nut

Square Nuts

Square Nuts

Combination Screws

Combination Screws

Pin

Pin

Nylon Locking Nuts

Nylon Locking Nuts

Pressure Rivet Nuts

Pressure Rivet Nuts

Cage Nut

Cage Nut

Welding Screws

Welding Screws

Butterfly Screw

Butterfly Screw

American Standard Butterfly Nut

American Standard Butterfly Nut

Expansion Screw

Expansion Screw

Plug Screw

Plug Screw

Stainless Steel Washer

Stainless Steel Washer

Double Overlap Anti-Loosening Washers

Double Overlap Anti-Loosening Washers

Waterproof and Anti-Drop Screws

Waterproof and Anti-Drop Screws

Super Corrosion-Resistant Screws

Super Corrosion-Resistant Screws

New Type Switchgear

New Type Switchgear

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Furniture Simple Assembly and Disassembly Connector

Furniture Simple Assembly and Disassembly Connector

Micro Vibration Absorber

Micro Vibration Absorber

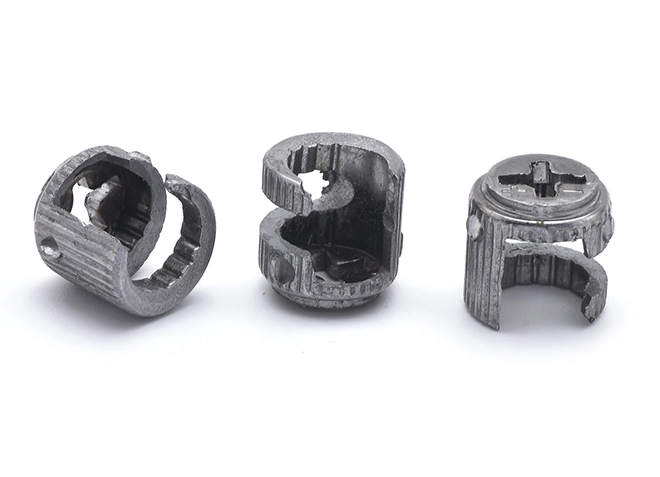

65Mn Material Furniture Connector

65Mn Material Furniture Connector

Counter Table Base

Counter Table Base

Furniture Connector Nut with Plastic Sleeve

Furniture Connector Nut with Plastic Sleeve

Furniture Horizontal Hole Nut

Furniture Horizontal Hole Nut

Furniture Connecting Screw

Furniture Connecting Screw

Furniture Connecting Nut Seat

Furniture Connecting Nut Seat

Double Stack Wheels Used On Furniture

Double Stack Wheels Used On Furniture

Components Used On Furniture

Components Used On Furniture

Connection Buckle

Connection Buckle

Internal Hexagonal Spiral Screw

Internal Hexagonal Spiral Screw

Iron Colored Carbon Steel Four Claw Nut

Iron Colored Carbon Steel Four Claw Nut

Iron Furniture Three Combination Nut Seat

Iron Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

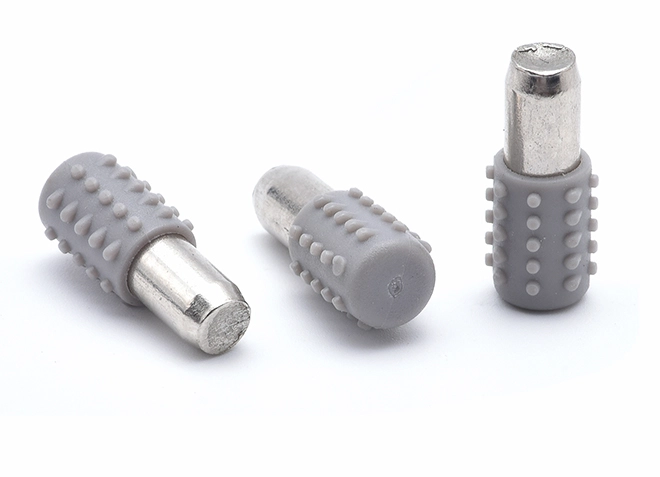

Dowel Pin+ Gray Elephant Rubber Sleeve

Dowel Pin+ Gray Elephant Rubber Sleeve

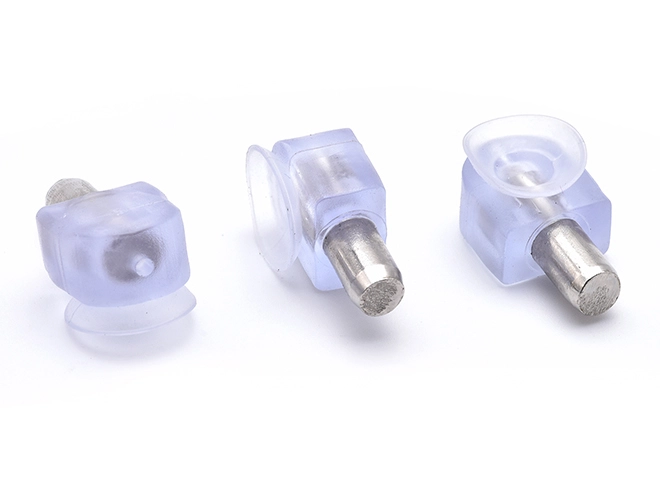

Dowel Pin+ Transparent Elephant Rubber Sleeve

Dowel Pin+ Transparent Elephant Rubber Sleeve

Injection Molded Furniture Foot Pad Screw

Injection Molded Furniture Foot Pad Screw

An anti-loose waterproof screw is a specialized fastener engineered to resist loosening and prevent water infiltration in various applications, particularly in environments where moisture exposure is a concern. The waterproofing aspect is achieved through rubber gaskets, O-rings, or sealants applied to the screw threads or under the screw head, creating a tight seal that prevents water from seeping into the joint or material being fastened. Anti-loose waterproof screws find applications in outdoor construction, marine, automotive, and other industries where maintaining a secure and watertight connection is essential for durability and reliability.

Advanced Coatings and Materials: Future innovations in anti-loose waterproof screws are likely to focus on the development of more advanced coatings and materials. This includes the use of nanotechnology to create ultra-thin, highly effective corrosion-resistant coatings that enhance waterproofing and longevity. Advanced materials, such as high-performance polymers or composites, may also be employed to improve the strength and flexibility of these screws.

Enhanced Anti-loose Mechanisms: New designs will likely feature more sophisticated anti-loose mechanisms. Innovations may include integrated locking systems that provide better resistance to vibrations and dynamic forces. For instance, self-locking threads or built-in nylon inserts could become more prevalent, offering superior grip and preventing unintentional loosening in various applications.

Improved Manufacturing Techniques: Advances in manufacturing technology, such as additive manufacturing (3D printing) and precision machining, will enhance the production of waterproof screws. These techniques will enable the creation of complex designs and high-precision threads, improving the overall performance and functionality of the screws.

Integration with Other Fasteners: There may be an increase in the development of hybrid fastening systems that combine anti-loose waterproof screws with other types of fasteners. This integration could optimize performance in applications requiring multiple types of fastening solutions, improving assembly efficiency and security.

arron18129983931@gmail.com

arron18129983931@gmail.com

arron18129983931@gmail.com