Aaron: +86-18129983931

Max: +86-18922922459

Micro Screws

Micro Screws

Big Head Screws

Big Head Screws

Construction Screws

Construction Screws

CNC Lathe Machining Parts

CNC Lathe Machining Parts

Cold Forged and Undergo Secondary Processing Products

Cold Forged and Undergo Secondary Processing Products

Multi Station Cold Heading Screws

Multi Station Cold Heading Screws

Step Screw

Step Screw

Automatic Lathe Machining Parts

Automatic Lathe Machining Parts

High Difficulty Challenge Cold Heading Fasteners

High Difficulty Challenge Cold Heading Fasteners

New Tech Fasteners

New Tech Fasteners

Machine Screws

Machine Screws

Socket Cap Screws

Socket Cap Screws

Hexagon Socket Set Screws

Hexagon Socket Set Screws

Pull Out Rivet

Pull Out Rivet

Self Tapping Screws

Self Tapping Screws

Hex Bolts

Hex Bolts

Self Drilling Screws

Self Drilling Screws

Eye Bolts

Eye Bolts

U-bolts

U-bolts

Threaded Sheath

Threaded Sheath

Hex Nut

Hex Nut

Hex Long Nut

Hex Long Nut

Pull Rivet Nut

Pull Rivet Nut

Square Nuts

Square Nuts

Combination Screws

Combination Screws

Pin

Pin

Nylon Locking Nuts

Nylon Locking Nuts

Pressure Rivet Nuts

Pressure Rivet Nuts

Cage Nut

Cage Nut

Welding Screws

Welding Screws

Butterfly Screw

Butterfly Screw

American Standard Butterfly Nut

American Standard Butterfly Nut

Expansion Screw

Expansion Screw

Plug Screw

Plug Screw

Stainless Steel Washer

Stainless Steel Washer

Double Overlap Anti-Loosening Washers

Double Overlap Anti-Loosening Washers

Waterproof and Anti-Drop Screws

Waterproof and Anti-Drop Screws

Super Corrosion-Resistant Screws

Super Corrosion-Resistant Screws

New Type Switchgear

New Type Switchgear

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Furniture Simple Assembly and Disassembly Connector

Furniture Simple Assembly and Disassembly Connector

Micro Vibration Absorber

Micro Vibration Absorber

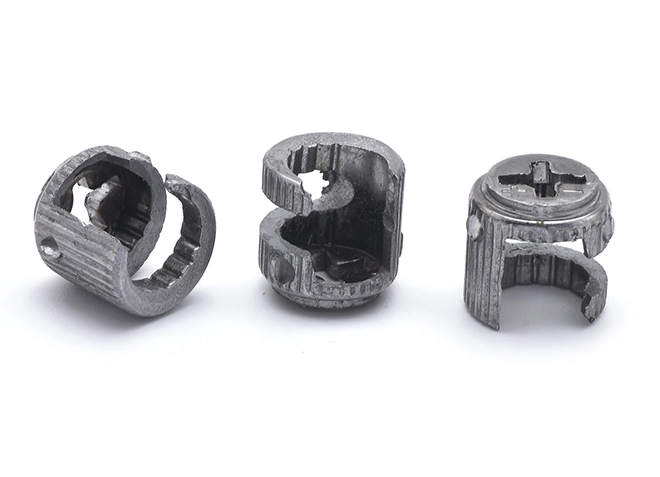

65Mn Material Furniture Connector

65Mn Material Furniture Connector

Counter Table Base

Counter Table Base

Furniture Connector Nut with Plastic Sleeve

Furniture Connector Nut with Plastic Sleeve

Furniture Horizontal Hole Nut

Furniture Horizontal Hole Nut

Furniture Connecting Screw

Furniture Connecting Screw

Furniture Connecting Nut Seat

Furniture Connecting Nut Seat

Double Stack Wheels Used On Furniture

Double Stack Wheels Used On Furniture

Components Used On Furniture

Components Used On Furniture

Connection Buckle

Connection Buckle

Internal Hexagonal Spiral Screw

Internal Hexagonal Spiral Screw

Iron Colored Carbon Steel Four Claw Nut

Iron Colored Carbon Steel Four Claw Nut

Iron Furniture Three Combination Nut Seat

Iron Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

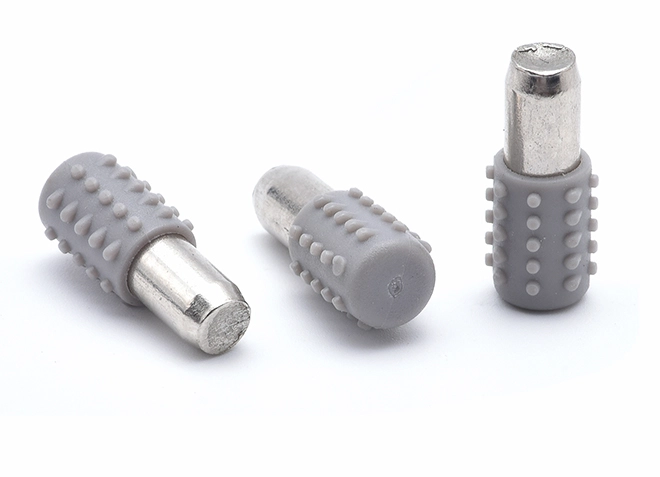

Dowel Pin+ Gray Elephant Rubber Sleeve

Dowel Pin+ Gray Elephant Rubber Sleeve

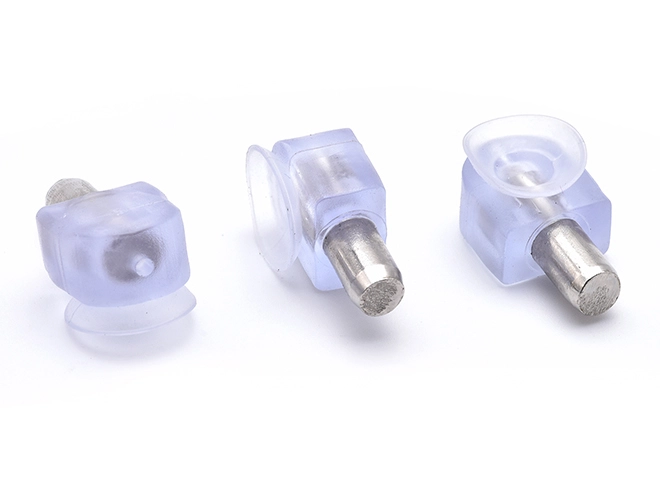

Dowel Pin+ Transparent Elephant Rubber Sleeve

Dowel Pin+ Transparent Elephant Rubber Sleeve

Injection Molded Furniture Foot Pad Screw

Injection Molded Furniture Foot Pad Screw

Creating a precision hexagonal joint involves detailed CAD design and material selection, typically high-strength alloys or stainless steel. Precision machining techniques, such as CNC milling, are used to achieve tight tolerances and smooth surfaces. Thorough quality control, including dimensional inspections and surface finish checks, ensures accuracy and durability. This process results in a high-precision component suitable for applications requiring exact alignment and robust mechanical performance.

Component Preparation: Ensure that all copper components are accurately machined and cleaned before assembly. Precision in machining is crucial for a proper fit and to avoid issues during integration. Components should be free of debris, oxidation, or any imperfections that could affect performance.

Alignment and Assembly: Align the copper hexagonal joints precisely. Use alignment tools or jigs to ensure that all parts fit together correctly. The hexagonal shape facilitates secure gripping and reduces the likelihood of slippage during assembly. Carefully thread or insert components to avoid cross-threading or misalignment.

Integration with Other Systems: When integrating the copper joint assembly into a larger system, ensure compatibility with adjoining components. Proper integration involves verifying that the joint fits well with other elements, such as pipes, circuits, or mechanical parts. Check for correct dimensions and tolerances to ensure seamless integration.

Securing the Assembly: Depending on the application, secure the hexagonal joint using appropriate methods. This may include tightening with a hexagonal wrench, applying sealants, or using locking mechanisms. Properly securing the assembly is critical to prevent leaks, movement, or failure under operational stresses.

Testing and Quality Control: After assembly and integration, conduct thorough testing to verify the functionality and integrity of the joint. Perform pressure tests, electrical tests, or functional checks based on the application requirements. Inspect the assembly for any signs of defects or issues that could impact performance.

Maintenance and Inspection: Regularly inspect and maintain the copper hexagonal joint assemblies to ensure continued performance. Periodic checks help identify any wear or damage early, allowing for timely maintenance or replacement to avoid operational failures.

arron18129983931@gmail.com

arron18129983931@gmail.com

arron18129983931@gmail.com