Aaron: +86-18129983931

Max: +86-18922922459

Micro Screws

Micro Screws

Big Head Screws

Big Head Screws

Construction Screws

Construction Screws

CNC Lathe Machining Parts

CNC Lathe Machining Parts

Cold Forged and Undergo Secondary Processing Products

Cold Forged and Undergo Secondary Processing Products

Multi Station Cold Heading Screws

Multi Station Cold Heading Screws

Step Screw

Step Screw

Automatic Lathe Machining Parts

Automatic Lathe Machining Parts

High Difficulty Challenge Cold Heading Fasteners

High Difficulty Challenge Cold Heading Fasteners

New Tech Fasteners

New Tech Fasteners

Machine Screws

Machine Screws

Socket Cap Screws

Socket Cap Screws

Hexagon Socket Set Screws

Hexagon Socket Set Screws

Pull Out Rivet

Pull Out Rivet

Self Tapping Screws

Self Tapping Screws

Hex Bolts

Hex Bolts

Self Drilling Screws

Self Drilling Screws

Eye Bolts

Eye Bolts

U-bolts

U-bolts

Threaded Sheath

Threaded Sheath

Hex Nut

Hex Nut

Hex Long Nut

Hex Long Nut

Pull Rivet Nut

Pull Rivet Nut

Square Nuts

Square Nuts

Combination Screws

Combination Screws

Pin

Pin

Nylon Locking Nuts

Nylon Locking Nuts

Pressure Rivet Nuts

Pressure Rivet Nuts

Cage Nut

Cage Nut

Welding Screws

Welding Screws

Butterfly Screw

Butterfly Screw

American Standard Butterfly Nut

American Standard Butterfly Nut

Expansion Screw

Expansion Screw

Plug Screw

Plug Screw

Stainless Steel Washer

Stainless Steel Washer

Double Overlap Anti-Loosening Washers

Double Overlap Anti-Loosening Washers

Waterproof and Anti-Drop Screws

Waterproof and Anti-Drop Screws

Super Corrosion-Resistant Screws

Super Corrosion-Resistant Screws

New Type Switchgear

New Type Switchgear

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Furniture Simple Assembly and Disassembly Connector

Furniture Simple Assembly and Disassembly Connector

Micro Vibration Absorber

Micro Vibration Absorber

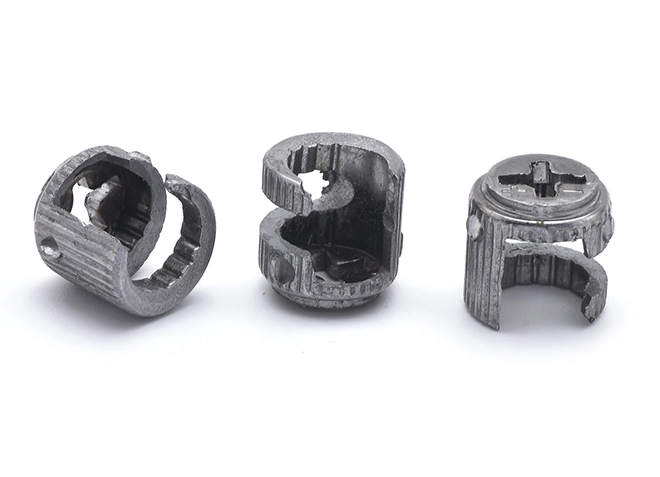

65Mn Material Furniture Connector

65Mn Material Furniture Connector

Counter Table Base

Counter Table Base

Furniture Connector Nut with Plastic Sleeve

Furniture Connector Nut with Plastic Sleeve

Furniture Horizontal Hole Nut

Furniture Horizontal Hole Nut

Furniture Connecting Screw

Furniture Connecting Screw

Furniture Connecting Nut Seat

Furniture Connecting Nut Seat

Double Stack Wheels Used On Furniture

Double Stack Wheels Used On Furniture

Components Used On Furniture

Components Used On Furniture

Connection Buckle

Connection Buckle

Internal Hexagonal Spiral Screw

Internal Hexagonal Spiral Screw

Iron Colored Carbon Steel Four Claw Nut

Iron Colored Carbon Steel Four Claw Nut

Iron Furniture Three Combination Nut Seat

Iron Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

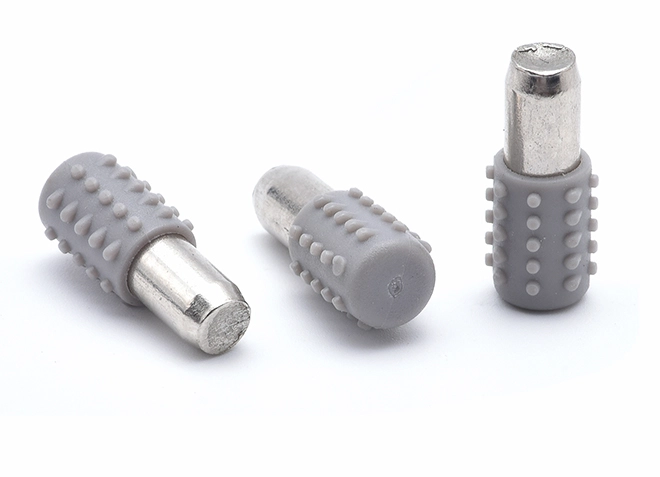

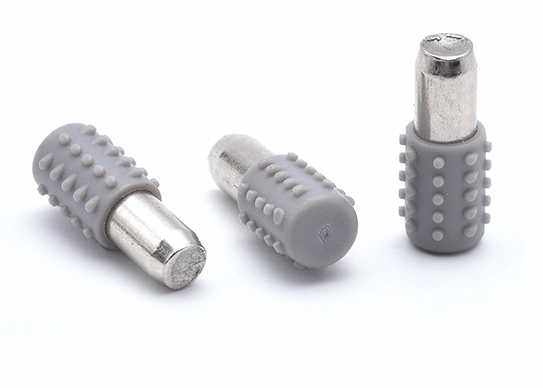

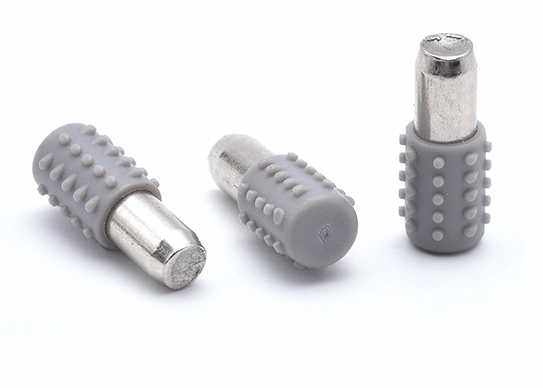

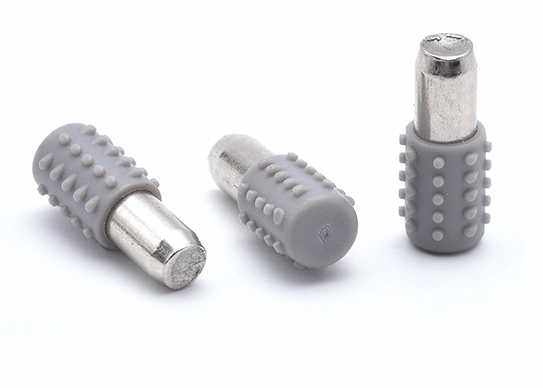

Dowel Pin+ Gray Elephant Rubber Sleeve

Dowel Pin+ Gray Elephant Rubber Sleeve

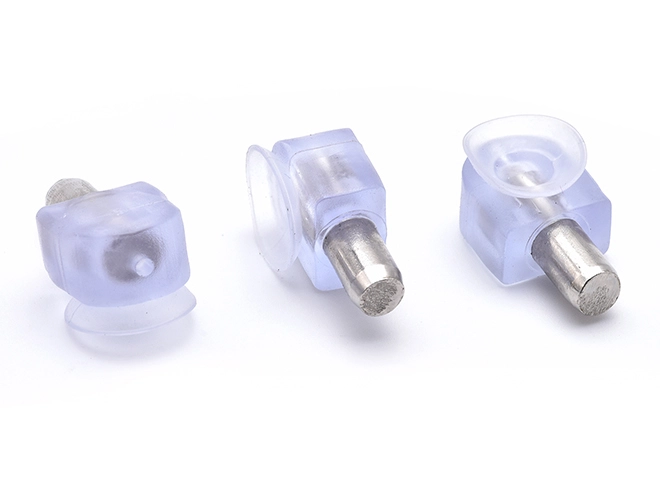

Dowel Pin+ Transparent Elephant Rubber Sleeve

Dowel Pin+ Transparent Elephant Rubber Sleeve

Injection Molded Furniture Foot Pad Screw

Injection Molded Furniture Foot Pad Screw

A dowel pin combined with a gray elephant rubber sleeve is a unique assembly solution often used in furniture construction and other applications requiring secure and vibration-resistant connections. The dowel pin serves as a cylindrical fastener, typically made of metal or wood, inserted into pre-drilled holes in two mating components to align and reinforce their connection. Meanwhile, the gray elephant rubber sleeve, which is a type of rubber or elastomeric material, provides cushioning, vibration dampening, and grip enhancement.

Prepare the Installation Area: Ensure that the surface where the integrated dowel pin and rubber sleeve will be installed is clean and free from debris, dust, or oil. This ensures a good fit and prevents contamination.

Check the Component: Verify that the integrated dowel pin and gray elephant rubber sleeve are intact and free from defects. Ensure that the rubber sleeve is securely attached to the dowel pin and is not damaged.

Align the Dowel Pin and Rubber Sleeve: Accurately mark the installation points where the dowel pin and rubber sleeve will be inserted. Proper alignment is crucial for a secure fit. Align the integrated product (dowel pin with rubber sleeve) with the marked location. Make sure the component is positioned correctly and is aligned with any pre-drilled holes or slots.

Insert the Component: Slide into Place: Gently insert the integrated dowel pin and rubber sleeve into the prepared hole or slot. Ensure that the rubber sleeve fits snugly around the dowel pin and that the component is fully seated. If necessary, apply gentle pressure to ensure that the component is properly inserted. Avoid using excessive force that could damage the rubber sleeve or misalign the pin.

Final Adjustments: If the component is not correctly positioned or if there are any issues, make the necessary adjustments to ensure proper installation.

arron18129983931@gmail.com

arron18129983931@gmail.com

arron18129983931@gmail.com