Aaron: +86-18129983931

Max: +86-18922922459

Micro Screws

Micro Screws

Big Head Screws

Big Head Screws

Construction Screws

Construction Screws

CNC Lathe Machining Parts

CNC Lathe Machining Parts

Cold Forged and Undergo Secondary Processing Products

Cold Forged and Undergo Secondary Processing Products

Multi Station Cold Heading Screws

Multi Station Cold Heading Screws

Step Screw

Step Screw

Automatic Lathe Machining Parts

Automatic Lathe Machining Parts

High Difficulty Challenge Cold Heading Fasteners

High Difficulty Challenge Cold Heading Fasteners

New Tech Fasteners

New Tech Fasteners

Machine Screws

Machine Screws

Socket Cap Screws

Socket Cap Screws

Hexagon Socket Set Screws

Hexagon Socket Set Screws

Pull Out Rivet

Pull Out Rivet

Self Tapping Screws

Self Tapping Screws

Hex Bolts

Hex Bolts

Self Drilling Screws

Self Drilling Screws

Eye Bolts

Eye Bolts

U-bolts

U-bolts

Threaded Sheath

Threaded Sheath

Hex Nut

Hex Nut

Hex Long Nut

Hex Long Nut

Pull Rivet Nut

Pull Rivet Nut

Square Nuts

Square Nuts

Combination Screws

Combination Screws

Pin

Pin

Nylon Locking Nuts

Nylon Locking Nuts

Pressure Rivet Nuts

Pressure Rivet Nuts

Cage Nut

Cage Nut

Welding Screws

Welding Screws

Butterfly Screw

Butterfly Screw

American Standard Butterfly Nut

American Standard Butterfly Nut

Expansion Screw

Expansion Screw

Plug Screw

Plug Screw

Stainless Steel Washer

Stainless Steel Washer

Double Overlap Anti-Loosening Washers

Double Overlap Anti-Loosening Washers

Waterproof and Anti-Drop Screws

Waterproof and Anti-Drop Screws

Super Corrosion-Resistant Screws

Super Corrosion-Resistant Screws

New Type Switchgear

New Type Switchgear

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Furniture Simple Assembly and Disassembly Connector

Furniture Simple Assembly and Disassembly Connector

Micro Vibration Absorber

Micro Vibration Absorber

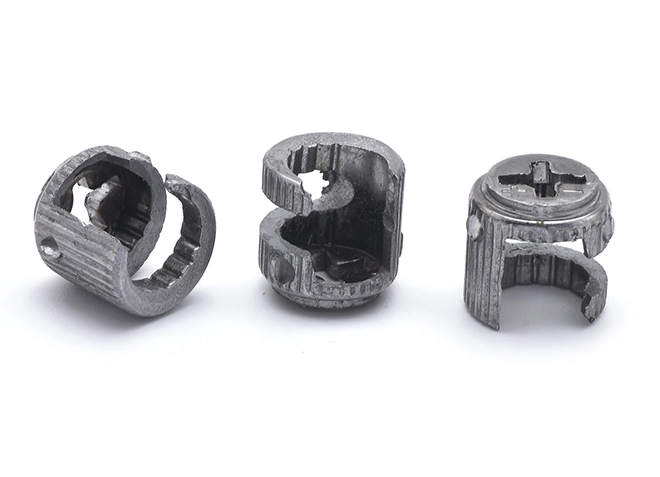

65Mn Material Furniture Connector

65Mn Material Furniture Connector

Counter Table Base

Counter Table Base

Furniture Connector Nut with Plastic Sleeve

Furniture Connector Nut with Plastic Sleeve

Furniture Horizontal Hole Nut

Furniture Horizontal Hole Nut

Furniture Connecting Screw

Furniture Connecting Screw

Furniture Connecting Nut Seat

Furniture Connecting Nut Seat

Double Stack Wheels Used On Furniture

Double Stack Wheels Used On Furniture

Components Used On Furniture

Components Used On Furniture

Connection Buckle

Connection Buckle

Internal Hexagonal Spiral Screw

Internal Hexagonal Spiral Screw

Iron Colored Carbon Steel Four Claw Nut

Iron Colored Carbon Steel Four Claw Nut

Iron Furniture Three Combination Nut Seat

Iron Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

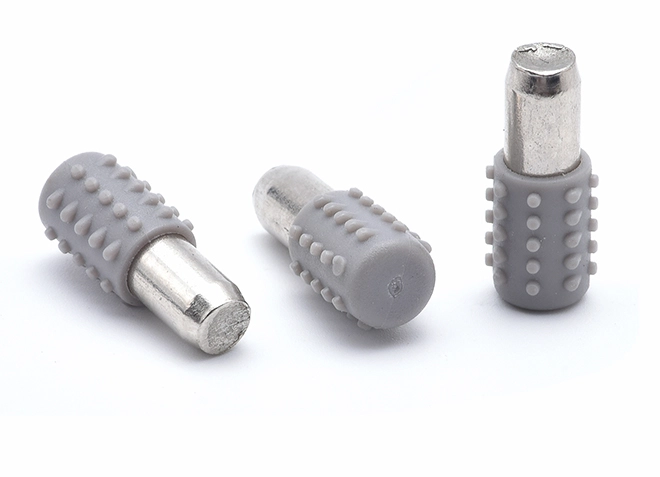

Dowel Pin+ Gray Elephant Rubber Sleeve

Dowel Pin+ Gray Elephant Rubber Sleeve

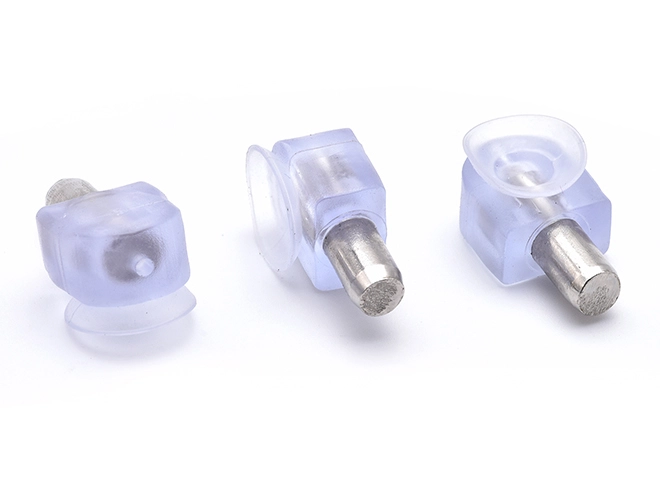

Dowel Pin+ Transparent Elephant Rubber Sleeve

Dowel Pin+ Transparent Elephant Rubber Sleeve

Injection Molded Furniture Foot Pad Screw

Injection Molded Furniture Foot Pad Screw

A small copper step screw on a medical device is a specialized fastener used in medical equipment or devices. These screws typically feature a small diameter and a step or shoulder on the shaft, allowing for precise insertion and secure fastening in delicate or compact assemblies.

Corrosion Resistance: Copper is naturally resistant to corrosion and oxidation, which is critical in medical devices exposed to bodily fluids or sterilization processes. This resistance helps maintain the integrity and performance of the screws over time, reducing the risk of device failure.

Biocompatibility: Copper is generally biocompatible, meaning it does not cause adverse reactions when in contact with body tissues. This property is essential for medical devices that come into direct or indirect contact with patients, ensuring that the screws do not trigger allergic reactions or other negative responses.

Precision and Reliability: Small copper step screws are manufactured to high precision, which ensures that they fit securely and function reliably in medical devices. Their precise design helps maintain the device's performance and safety by preventing loose or misaligned components.

Sterilization Compatibility: Copper can withstand various sterilization methods, such as autoclaving, without compromising its structural integrity. This compatibility ensures that the screws can be effectively sterilized before use, minimizing the risk of infection.

Durability: Copper's malleability and strength make it durable and able to withstand the mechanical stresses encountered in medical devices. This durability ensures that the screws remain securely fastened, which is crucial for the proper functioning of the device.

Low Magnetic Interference: Copper's non-magnetic properties are beneficial in medical devices that use magnetic imaging or require low magnetic interference, such as MRI-compatible devices. This helps prevent any disruption to diagnostic imaging or device functionality.

arron18129983931@gmail.com

arron18129983931@gmail.com

arron18129983931@gmail.com