Aaron: +86-18129983931

Max: +86-18922922459

Micro Screws

Micro Screws

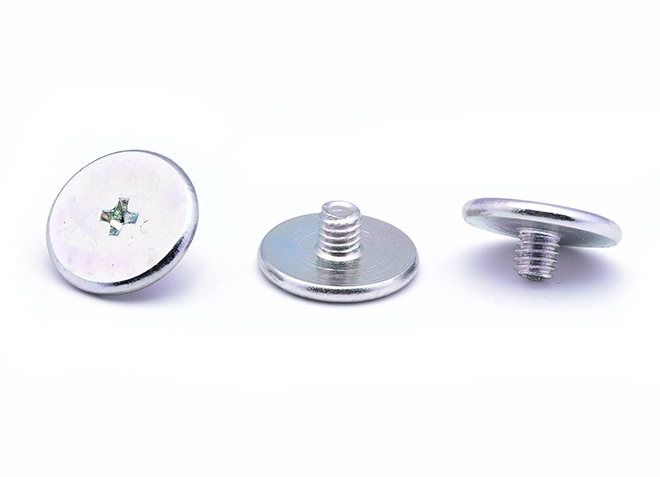

Big Head Screws

Big Head Screws

Construction Screws

Construction Screws

CNC Lathe Machining Parts

CNC Lathe Machining Parts

Cold Forged and Undergo Secondary Processing Products

Cold Forged and Undergo Secondary Processing Products

Multi Station Cold Heading Screws

Multi Station Cold Heading Screws

Step Screw

Step Screw

Automatic Lathe Machining Parts

Automatic Lathe Machining Parts

High Difficulty Challenge Cold Heading Fasteners

High Difficulty Challenge Cold Heading Fasteners

New Tech Fasteners

New Tech Fasteners

Machine Screws

Machine Screws

Socket Cap Screws

Socket Cap Screws

Hexagon Socket Set Screws

Hexagon Socket Set Screws

Pull Out Rivet

Pull Out Rivet

Self Tapping Screws

Self Tapping Screws

Hex Bolts

Hex Bolts

Self Drilling Screws

Self Drilling Screws

Eye Bolts

Eye Bolts

U-bolts

U-bolts

Threaded Sheath

Threaded Sheath

Hex Nut

Hex Nut

Hex Long Nut

Hex Long Nut

Pull Rivet Nut

Pull Rivet Nut

Square Nuts

Square Nuts

Combination Screws

Combination Screws

Pin

Pin

Nylon Locking Nuts

Nylon Locking Nuts

Pressure Rivet Nuts

Pressure Rivet Nuts

Cage Nut

Cage Nut

Welding Screws

Welding Screws

Butterfly Screw

Butterfly Screw

American Standard Butterfly Nut

American Standard Butterfly Nut

Expansion Screw

Expansion Screw

Plug Screw

Plug Screw

Stainless Steel Washer

Stainless Steel Washer

Double Overlap Anti-Loosening Washers

Double Overlap Anti-Loosening Washers

Waterproof and Anti-Drop Screws

Waterproof and Anti-Drop Screws

Super Corrosion-Resistant Screws

Super Corrosion-Resistant Screws

New Type Switchgear

New Type Switchgear

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Furniture Simple Assembly and Disassembly Connector

Furniture Simple Assembly and Disassembly Connector

Micro Vibration Absorber

Micro Vibration Absorber

65Mn Material Furniture Connector

65Mn Material Furniture Connector

Counter Table Base

Counter Table Base

Furniture Connector Nut with Plastic Sleeve

Furniture Connector Nut with Plastic Sleeve

Furniture Horizontal Hole Nut

Furniture Horizontal Hole Nut

Furniture Connecting Screw

Furniture Connecting Screw

Furniture Connecting Nut Seat

Furniture Connecting Nut Seat

Double Stack Wheels Used On Furniture

Double Stack Wheels Used On Furniture

Components Used On Furniture

Components Used On Furniture

Connection Buckle

Connection Buckle

Internal Hexagonal Spiral Screw

Internal Hexagonal Spiral Screw

Iron Colored Carbon Steel Four Claw Nut

Iron Colored Carbon Steel Four Claw Nut

Iron Furniture Three Combination Nut Seat

Iron Furniture Three Combination Nut Seat

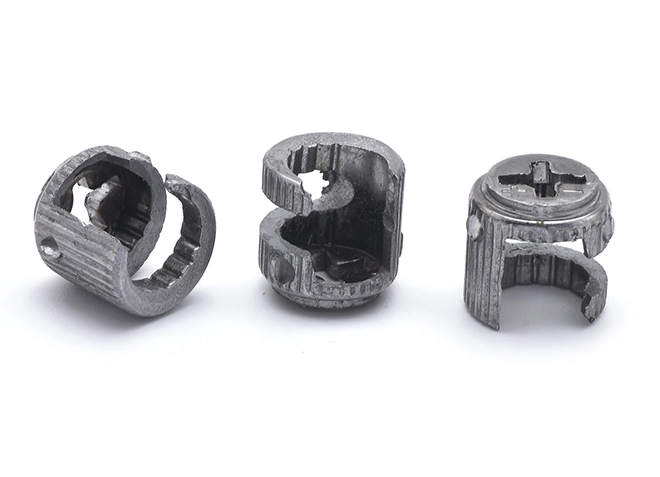

Iron and Zinc Alloy Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

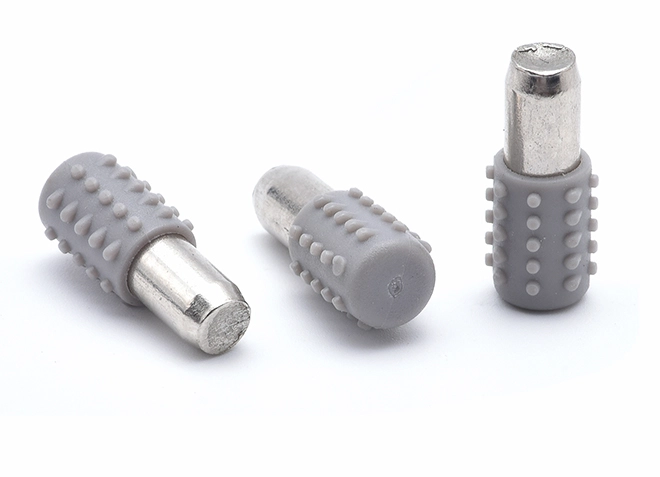

Dowel Pin+ Gray Elephant Rubber Sleeve

Dowel Pin+ Gray Elephant Rubber Sleeve

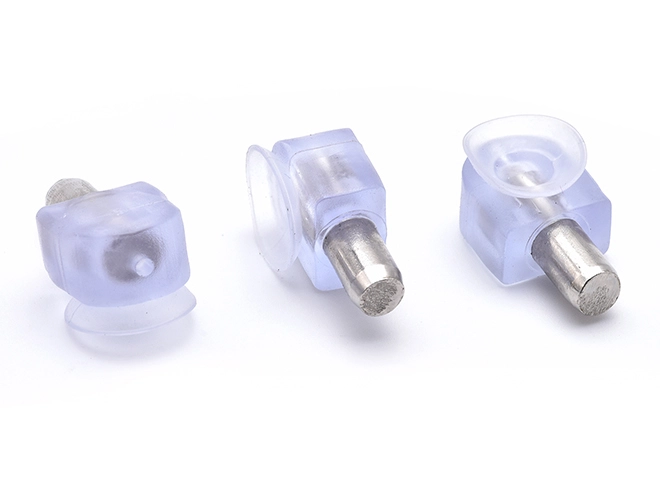

Dowel Pin+ Transparent Elephant Rubber Sleeve

Dowel Pin+ Transparent Elephant Rubber Sleeve

Injection Molded Furniture Foot Pad Screw

Injection Molded Furniture Foot Pad Screw

Cold heading, also known as cold forming, is a manufacturing process used to shape metal into various parts such as bolts, screws, and other fasteners. It involves forcing a metal blank into a die under high pressure, causing the metal to flow and form into the desired shape without removing any material. This process is highly efficient and cost-effective for producing large quantities of parts.

Advanced Materials: Using high-quality, wear-resistant tool materials.

Precision Engineering: Investing in precise die design and manufacturing.

Process Optimization: Fine-tuning the process parameters for optimal performance.

Heat Treatment: Pre-treating materials to improve formability.

Lubrication: Using effective lubricants to reduce friction and wear.

| Feature | Cold Heading | Machining | Hot Forging |

| Material Waste | Minimal | High | Moderate |

| Strength | High | Lower | High |

| Production Speed | Fast | Slow | Moderate |

| Cost-Effectiveness | Excellent | Expensive | Costly |

Geometry: Keep designs simple for better formability.

Material Selection: Choose materials compatible with cold forming.

Tolerances: Account for minor variations in the forming process.

Material Selection: Choose the appropriate wire or rod material.

Wire Preparation: Clean and straighten the material.

Cutting: Cut to precise lengths.

Forming: Use dies and punches to create the shape.

Trimming: Remove excess material if needed.

Secondary Operations: Threading or heat treatment.