Aaron: +86-18129983931

Max: +86-18922922459

Micro Screws

Micro Screws

Big Head Screws

Big Head Screws

Construction Screws

Construction Screws

CNC Lathe Machining Parts

CNC Lathe Machining Parts

Cold Forged and Undergo Secondary Processing Products

Cold Forged and Undergo Secondary Processing Products

Multi Station Cold Heading Screws

Multi Station Cold Heading Screws

Step Screw

Step Screw

Automatic Lathe Machining Parts

Automatic Lathe Machining Parts

High Difficulty Challenge Cold Heading Fasteners

High Difficulty Challenge Cold Heading Fasteners

New Tech Fasteners

New Tech Fasteners

Machine Screws

Machine Screws

Socket Cap Screws

Socket Cap Screws

Hexagon Socket Set Screws

Hexagon Socket Set Screws

Pull Out Rivet

Pull Out Rivet

Self Tapping Screws

Self Tapping Screws

Hex Bolts

Hex Bolts

Self Drilling Screws

Self Drilling Screws

Eye Bolts

Eye Bolts

U-bolts

U-bolts

Threaded Sheath

Threaded Sheath

Hex Nut

Hex Nut

Hex Long Nut

Hex Long Nut

Pull Rivet Nut

Pull Rivet Nut

Square Nuts

Square Nuts

Combination Screws

Combination Screws

Pin

Pin

Nylon Locking Nuts

Nylon Locking Nuts

Pressure Rivet Nuts

Pressure Rivet Nuts

Cage Nut

Cage Nut

Welding Screws

Welding Screws

Butterfly Screw

Butterfly Screw

American Standard Butterfly Nut

American Standard Butterfly Nut

Expansion Screw

Expansion Screw

Plug Screw

Plug Screw

Stainless Steel Washer

Stainless Steel Washer

Double Overlap Anti-Loosening Washers

Double Overlap Anti-Loosening Washers

Waterproof and Anti-Drop Screws

Waterproof and Anti-Drop Screws

Super Corrosion-Resistant Screws

Super Corrosion-Resistant Screws

New Type Switchgear

New Type Switchgear

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Furniture Simple Assembly and Disassembly Connector

Furniture Simple Assembly and Disassembly Connector

Micro Vibration Absorber

Micro Vibration Absorber

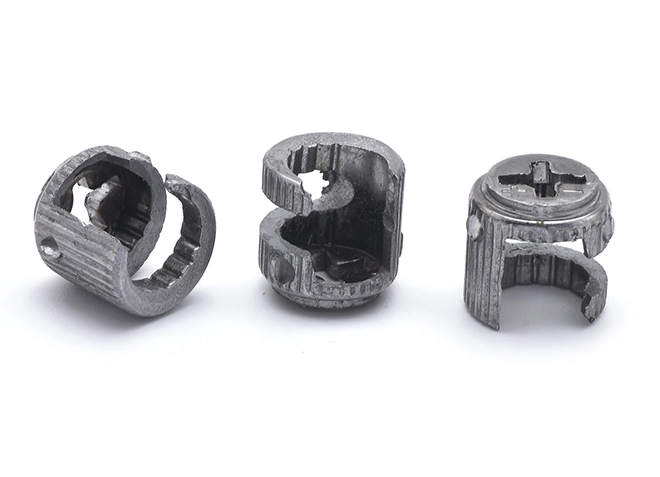

65Mn Material Furniture Connector

65Mn Material Furniture Connector

Counter Table Base

Counter Table Base

Furniture Connector Nut with Plastic Sleeve

Furniture Connector Nut with Plastic Sleeve

Furniture Horizontal Hole Nut

Furniture Horizontal Hole Nut

Furniture Connecting Screw

Furniture Connecting Screw

Furniture Connecting Nut Seat

Furniture Connecting Nut Seat

Double Stack Wheels Used On Furniture

Double Stack Wheels Used On Furniture

Components Used On Furniture

Components Used On Furniture

Connection Buckle

Connection Buckle

Internal Hexagonal Spiral Screw

Internal Hexagonal Spiral Screw

Iron Colored Carbon Steel Four Claw Nut

Iron Colored Carbon Steel Four Claw Nut

Iron Furniture Three Combination Nut Seat

Iron Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

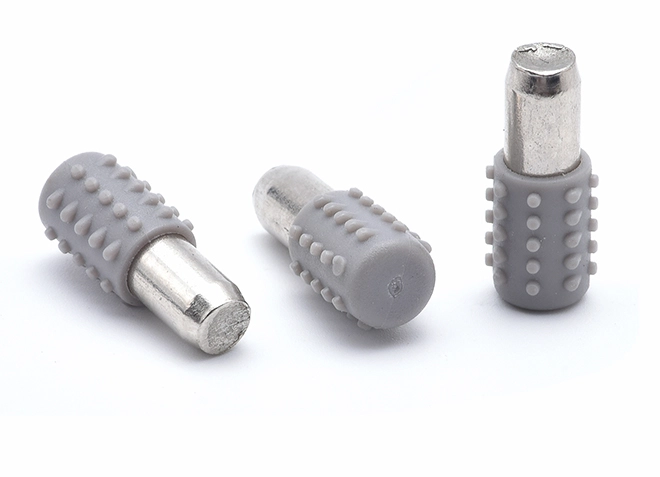

Dowel Pin+ Gray Elephant Rubber Sleeve

Dowel Pin+ Gray Elephant Rubber Sleeve

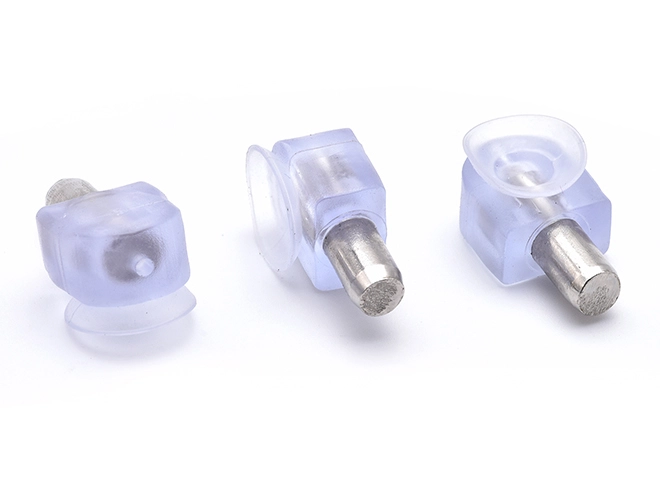

Dowel Pin+ Transparent Elephant Rubber Sleeve

Dowel Pin+ Transparent Elephant Rubber Sleeve

Injection Molded Furniture Foot Pad Screw

Injection Molded Furniture Foot Pad Screw

A precision cylinder pin, commonly referred to as a dowel pin, is a type of fastener that is primarily used to locate components with respect to each other and to maintain an accurate alignment between them. These pins are cylindrical and are precisely machined to have tight tolerances, making them essential in high-precision engineering applications.

DIN 6325: A widely recognized international standard for precision dowel pins that specifies dimensions, tolerances, and material properties, including diameter and length tolerances such as H6 or H7.

ANSI/ASME B18.8.2: An American standard detailing dimensions and tolerances for dowel pins, ensuring uniformity and compatibility in North American applications. It covers different pin types and their specific measurements.

ISO 2338: An international standard that outlines the dimensions and tolerances for dowel pins, ensuring global consistency and interchangeability in precision applications.

Materials and Finishes: Precision cylinder pins are typically made from high-carbon steel, stainless steel, or other durable alloys. They may undergo surface treatments like coating or grinding to enhance properties such as corrosion resistance and smoothness.

Tolerance Classes: Tolerance classes, such as H6 and H7, indicate the precision of the pins. For example, H7 provides a tighter tolerance compared to H6, ensuring higher accuracy for demanding applications.

Nominal diameter (d) | |||

| d ① | m6 | Maximum value | |

| Minimum value | |||

| h8 | Maximum value | ||

| Minimum value | |||

| c | ≈ | ||

| Thousand pieces of steel weigh ≈ kg | |||

Nominal diameter (d) | |||

| d ① | m6 | Maximum value | |

| Minimum value | |||

| h8 | Maximum value | ||

| Minimum value | |||

| c | ≈ | ||

| Thousand pieces of steel weigh ≈ kg | |||

①, Other tolerances are subject to agreement between the supplier and the buyer. | |||

| Φ0.6 | Φ0.8 | Φ1 | Φ1.2 | Φ1.5 | Φ2 | Φ2.5 | Φ3 | Φ4 | Φ5 |

| 0.608 | 0.808 | 1.008 | 1.208 | 1.508 | 2.008 | 2.508 | 3.008 | 4.012 | 5.012 |

| 0.602 | 0.802 | 1.002 | 1.202 | 1.502 | 2.002 | 2.502 | 3.002 | 4.004 | 5.004 |

| 0.6 | 0.8 | 1 | 1.2 | 1.5 | 2 | 2.5 | 3 | 4 | 5 |

| 0.586 | 0.786 | 0.986 | 1.186 | 1.486 | 1.986 | 2.486 | 2.986 | 3.982 | 4.982 |

| 0.12 | 0.16 | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.5 | 0.63 | 0.8 |

| - | - | - | - | - | - | - | - | - | - |

| Φ6 | Φ8 | Φ10 | Φ12 | Φ16 | Φ20 | Φ25 | Φ30 | Φ40 | Φ50 |

| 6.012 | 8.015 | 10.015 | 12.018 | 16.018 | 20.021 | 25.021 | 30.021 | 40.025 | 50.025 |

| 6.004 | 8.006 | 10.006 | 12.007 | 16.007 | 20.008 | 25.008 | 30.008 | 40.009 | 50.009 |

| 6 | 8 | 10 | 12 | 16 | 20 | 25 | 30 | 40 | 50 |

| 5.982 | 7.978 | 9.978 | 11.973 | 15.973 | 19.967 | 24.967 | 29.967 | 39.961 | 49.961 |

| 1.2 | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6.3 | 8 |

| - | - | - | - | - | - | - | - | - | - |

arron18129983931@gmail.com

arron18129983931@gmail.com

arron18129983931@gmail.com