Aaron: +86-18129983931

Max: +86-18922922459

Micro Screws

Micro Screws

Big Head Screws

Big Head Screws

Construction Screws

Construction Screws

CNC Lathe Machining Parts

CNC Lathe Machining Parts

Cold Forged and Undergo Secondary Processing Products

Cold Forged and Undergo Secondary Processing Products

Multi Station Cold Heading Screws

Multi Station Cold Heading Screws

Step Screw

Step Screw

Automatic Lathe Machining Parts

Automatic Lathe Machining Parts

High Difficulty Challenge Cold Heading Fasteners

High Difficulty Challenge Cold Heading Fasteners

New Tech Fasteners

New Tech Fasteners

Machine Screws

Machine Screws

Socket Cap Screws

Socket Cap Screws

Hexagon Socket Set Screws

Hexagon Socket Set Screws

Pull Out Rivet

Pull Out Rivet

Self Tapping Screws

Self Tapping Screws

Hex Bolts

Hex Bolts

Self Drilling Screws

Self Drilling Screws

Eye Bolts

Eye Bolts

U-bolts

U-bolts

Threaded Sheath

Threaded Sheath

Hex Nut

Hex Nut

Hex Long Nut

Hex Long Nut

Pull Rivet Nut

Pull Rivet Nut

Square Nuts

Square Nuts

Combination Screws

Combination Screws

Pin

Pin

Nylon Locking Nuts

Nylon Locking Nuts

Pressure Rivet Nuts

Pressure Rivet Nuts

Cage Nut

Cage Nut

Welding Screws

Welding Screws

Butterfly Screw

Butterfly Screw

American Standard Butterfly Nut

American Standard Butterfly Nut

Expansion Screw

Expansion Screw

Plug Screw

Plug Screw

Stainless Steel Washer

Stainless Steel Washer

Double Overlap Anti-Loosening Washers

Double Overlap Anti-Loosening Washers

Waterproof and Anti-Drop Screws

Waterproof and Anti-Drop Screws

Super Corrosion-Resistant Screws

Super Corrosion-Resistant Screws

New Type Switchgear

New Type Switchgear

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Furniture Simple Assembly and Disassembly Connector

Furniture Simple Assembly and Disassembly Connector

Micro Vibration Absorber

Micro Vibration Absorber

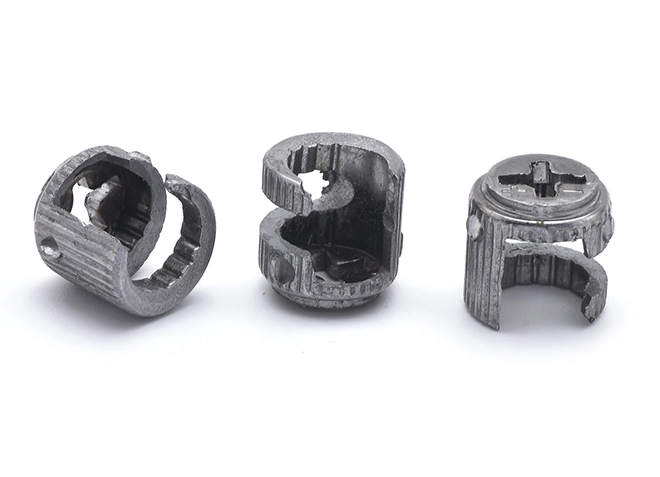

65Mn Material Furniture Connector

65Mn Material Furniture Connector

Counter Table Base

Counter Table Base

Furniture Connector Nut with Plastic Sleeve

Furniture Connector Nut with Plastic Sleeve

Furniture Horizontal Hole Nut

Furniture Horizontal Hole Nut

Furniture Connecting Screw

Furniture Connecting Screw

Furniture Connecting Nut Seat

Furniture Connecting Nut Seat

Double Stack Wheels Used On Furniture

Double Stack Wheels Used On Furniture

Components Used On Furniture

Components Used On Furniture

Connection Buckle

Connection Buckle

Internal Hexagonal Spiral Screw

Internal Hexagonal Spiral Screw

Iron Colored Carbon Steel Four Claw Nut

Iron Colored Carbon Steel Four Claw Nut

Iron Furniture Three Combination Nut Seat

Iron Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

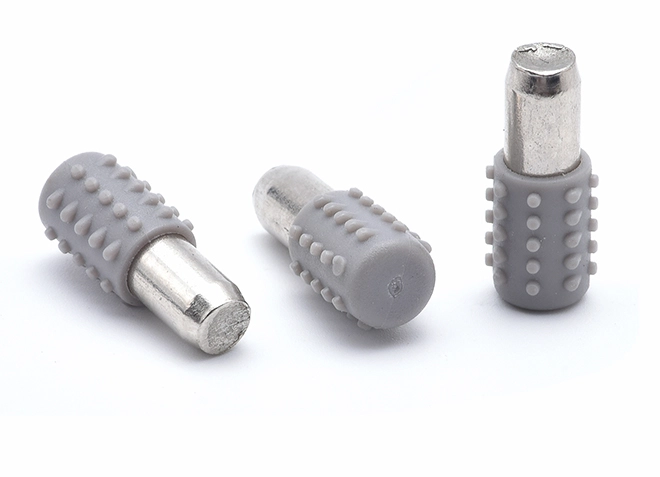

Dowel Pin+ Gray Elephant Rubber Sleeve

Dowel Pin+ Gray Elephant Rubber Sleeve

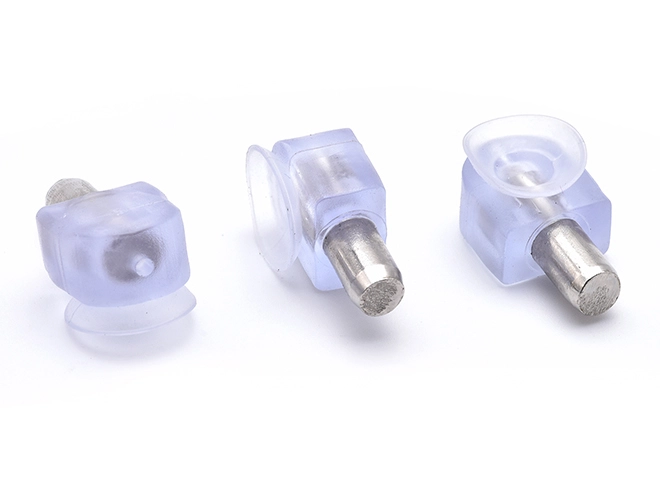

Dowel Pin+ Transparent Elephant Rubber Sleeve

Dowel Pin+ Transparent Elephant Rubber Sleeve

Injection Molded Furniture Foot Pad Screw

Injection Molded Furniture Foot Pad Screw

Pull-out rivets, also known as blind rivets or pop rivets, are versatile fasteners used in a variety of applications. Here are some common uses:

Automotive Industry

Body Panels: Used to attach car body panels and trim components.

Interior Components: Fasten interior panels, trim pieces, and seat assemblies.

Construction

Metal and Wood Construction: Secure metal sheets, siding, and wooden panels.

HVAC Installations: Attach ducts and other components in heating, ventilation, and air conditioning systems.

Aerospace

Aircraft Assembly: Secure skin panels, structural components, and interior fittings.

Electronics

Enclosures: Attach covers and panels on electronic enclosures and devices.

Furniture

Assembly: Fasten parts of metal or wooden furniture, such as chair frames and tables.

Manufacturing

Product Assembly: Used in various products and machinery to join components.

Signage

Outdoor Signs: Attach signs to poles, walls, or other structures.

Pull-out rivets are popular for their ease of installation, reliability, and the ability to fasten materials from one side only, making them ideal for situations where access to both sides of the workpiece is limited.

Nominal diameter d | |

| d | Maximum |

| Minimum | |

| dk | Maximum |

| Minimum | |

| k | ≈ |

| L1 | Minimum |

Material: a) Rivet body cast aluminum alloy: AlMgSi0.5, AlMg2.5 or AlMg3/ DIN 1725-1, or AlMg3.5/ ISO 209-1 Nail core material: steel wire (St) stainless steel (A2) b) Rivet body steel (St), St35/DIN 2391-2, QSt32-3 or QSt36-3/DIN 1654-2, or St4/DIN 1624 Nail core material: steel wire (St) c) Stainless steel (A2) according to DIN 267-11 Nail core material: steel wire (St), stainless steel (A2) d) Rivet body forged nickel alloy (NiCu), or NiCu30Fe/DIN 17743 Nail core material: steel wire (St), stainless steel (A2) e) Rivet body forged copper alloy (CuNi), or CuNi30Mn1Fe/DIN 17664 Nail core material: steel wire (St), stainless steel (A2) f) Rivet body copper (Cu), or E-Cu57/DIN 1787 Nail core material: steel wire (St), stainless steel (A2), bronze wire (CuSn) | |

| Φ3 | Φ3.2 | Φ4 | Φ4.8 | Φ5 | Φ6 | Φ6.4 |

| 3.08 | 3.28 | 4.08 | 4.88 | 5.08 | 6.08 | 6.48 |

| 2.9 | 3.1 | 3.85 | 4.65 | 4.85 | 5.85 | 6.25 |

| 6 | 6 | 7.5 | 9 | 9 | 11 | 12 |

| 5.6 | 5.6 | 7 | 8.5 | 8.5 | 10.3 | 11.3 |

| 0.9 | 0.9 | 1 | 1.2 | 1.2 | 1.5 | 1.6 |

| 27 | 27 | 27 | 27 | 27 | 27 | 27 |

arron18129983931@gmail.com

arron18129983931@gmail.com

arron18129983931@gmail.com